We are coming into a new season of nature with emerging flowers, nesting birds, new gardens, and sunny, warmer days.

It is a time of anticipation of all the new things emerging from the winter hibernation. There is excitement and anticipation in the air. There is hope for new things. Spring is all about change and renewal.

There is also hope for new relationships with our families, friends, and co-workers. The bright, warm sun warms us all.

Suppose we have a new season at work where we develop stronger, more supportive relationships among us. Just imagine the positive impact this would have. There would probably be a lot fewer people getting hurt and a lot less toxicity if our workplaces were filled with caring and support.

New Relationships

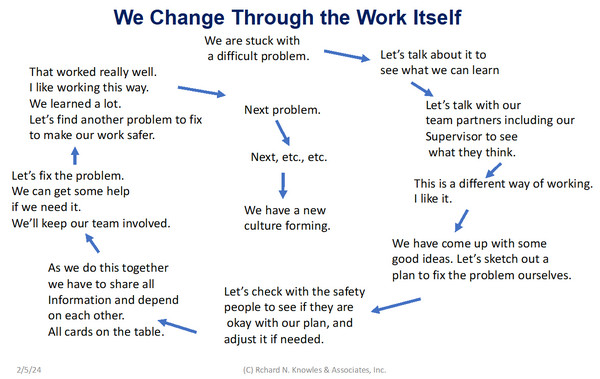

In our February blog post, I introduced the idea of a Cycle of Change, which I show here.

How much stronger would this Cycle of Change be if we could work together in an environment of caring and support? What would the morale look like? Would we be looking out for each other and helping where we could? Would we have more open conversations about what is going on and how we could improve things? Would there be a lot less bullying, dysfunction, and workplace violence? Would there be less fear and anxiety? Would the level of understanding among all organizational levels be a lot better? Would conflict between the people on the floor and the supervisors be less? Would we be growing a more sustainable, stronger culture? Would safety and environmental performance be better? Would productivity, quality, cost effectiveness, competitiveness be better?

It is interesting to think that all these would improve by just working on supporting and caring for each other. How we chose to work together has a big impact.

There are a lot of “would” words written above. And this one is used pointedly…Would that we all could understand and embrace this fundamental of life: “We change through the work we do together.” Leaders, especially need to connect these dots!

Making Our Choice

Who decides that supporting and caring are important relationships to work on? Who will make you work this way? Are the ideas of support and caring important to you?

If they are important, can you act on them and spread this way of working, one person at a time? Can you help, and support each other as you spread this way of working?

Each of us can make a positive impact if we want to. What do you want? What do you decide?

Call me at 716-622-6467 and I’ll walk you through how quickly and easily you can adopt this framework to your business, your team, your group.