The background story:

A recent article in the October 13, 2016 Daily Mail reported a £1.6 Million fine (equivalent of $2 Million) against Disney after actor, Harrison Ford, was crushed by the Millennium Falcon’s hydraulic door on the set of the latest Star Wars Episode VII, “The Force Awakens”, movie which was being filmed in June, 2014.

A recent article in the October 13, 2016 Daily Mail reported a £1.6 Million fine (equivalent of $2 Million) against Disney after actor, Harrison Ford, was crushed by the Millennium Falcon’s hydraulic door on the set of the latest Star Wars Episode VII, “The Force Awakens”, movie which was being filmed in June, 2014.

Ford had gone through the door, hit a button, walked out the door, and unexpectedly turned to walk back through the door when it came down on him. He assumed that the set was not live since it was a rehearsal. In this scene, Ford was helping his injured Wookiee friend through the door into the spacecraft. The door, which was operated by a person who was remotely located and could not see Ford, quickly closed it as he unexpectedly turned back into the spacecraft. Ford screamed and an emergency stop button was pressed, stopping the door just eight inches from being completely shut. They described it like a blunt-edged guillotine with a force comparable to being hit by a small car. Ford was pinned to the ground, suffering a broken tibia and fibula, a dislocated ankle and cut hand. The door had to be opened by the operator.

Disney’s subsidiary, Foodles Production (UK) Ltd., admitted to two counts of safety violations. In the main violation, while the company had done a risk assessment recognizing the risk of death, they had failed to talk to Ford so he was unaware of the precautions he needed to take. In earlier films, the door was operated slowly by a rope and pulley by a stagehand. The mechanized operation moved the door very quickly, surprising the 71-year-old Ford. After Ford’s recovery of about eight weeks, the film was completed.

The Meaning of the Story: Looking at the Blunt End and the Sharp End of Safety

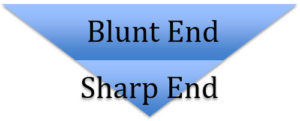

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

Relating this Story to Safety Theory and Practice

In Erik Hollnagel’s book, “Safety-I and Safety-II” (2014. Ashgate Publishing Ltd., Surrey, UK), he discusses ideas like the significance of the gap between “the work-as-imagined” done by managers and engineers planning and designing the work and the “work-as-done” by the people actually doing the work. This is illustrated nicely by the Ford Star Wars incident where the people doing the “work-as-imagined” failed to understand the actual conditions and mindset of Ford doing the “work-as-done.”

In Erik Hollnagel’s book, “Safety-I and Safety-II” (2014. Ashgate Publishing Ltd., Surrey, UK), he discusses ideas like the significance of the gap between “the work-as-imagined” done by managers and engineers planning and designing the work and the “work-as-done” by the people actually doing the work. This is illustrated nicely by the Ford Star Wars incident where the people doing the “work-as-imagined” failed to understand the actual conditions and mindset of Ford doing the “work-as-done.”

Hollnagel describes the way in which we have traditionally done our safety work as reactive and where so much of it relates to “work-as-imagined” as Safety-I. The gap between where the “work-as-imagined” and “work-as-done” is where there are very difficult communication challenges. We tend to react to what has gone wrong. Bridging this gap moves our safety work into Safety-II where we move into the world of more performance variability, more adaptability and resilience. This is a world where everyone needs a better understanding of how and why things work, particularly our organizations. It is a world where we need to have a sense of both the whole and the parts. It is a world where we focus more on understanding what is going right than just on what went wrong. It is a world where we are more proactive in our safety work.

The Bottom Line: Re-engaging the Force…People and Business Together

At Richard N. Knowles & Associates, we help organizations move into a world similar to Hollnagel’s Safety-II world. Our work environments and tasks are complex. Our organizations are complex, adapting, self-organizing networks of people. Building on these ideas, we help organizations to learn how to open up the communications, to engage everyone, to help and support each other, to listen and learn from each other, and connect real caring with the work that needs to be done. We help organizations to reconcile the relationship between the needs of the business and the needs of the people, which results in the release of enormous energy and creativity.

Give us a call so we can explore this more fully with you and help you see the sorts of improvements you and your people can make. We are here at 716-622-6467 to meet your needs.

Consider the Golden Gate Suspension Bridge (San Francisco) built between 1933 and 1937, an architectural marvel, thought to be impossible because in order to bridge that 6,700 ft. strait, in the middle of the bay channel, against strong tides, fierce winds, and thick fog, meant overcoming almost impossible odds. But it was built, with a grand opening in May of 1937, deemed, at the time of its completion, to be the tallest suspension bridge in the world as well as the longest. A man named Joseph Strauss engineered many new ideas, including developing safety devices such as movable netting, which saved 19 lives; though in all, there were 11 men lost during this construction. Thousands of men – workers of varying ages and from varied ethnic groups – came together to complete this project. (They had to listen and learn to be successful together.)

Consider the Golden Gate Suspension Bridge (San Francisco) built between 1933 and 1937, an architectural marvel, thought to be impossible because in order to bridge that 6,700 ft. strait, in the middle of the bay channel, against strong tides, fierce winds, and thick fog, meant overcoming almost impossible odds. But it was built, with a grand opening in May of 1937, deemed, at the time of its completion, to be the tallest suspension bridge in the world as well as the longest. A man named Joseph Strauss engineered many new ideas, including developing safety devices such as movable netting, which saved 19 lives; though in all, there were 11 men lost during this construction. Thousands of men – workers of varying ages and from varied ethnic groups – came together to complete this project. (They had to listen and learn to be successful together.) Consider the feat of building the monumental Hoover Dam (1931-1936) – a miracle of technology and engineering. No dam project of this scale had ever been attempted before. There were 21,000 people working at that site with approximately 100 industrial deaths. The walls for this structure – that would uphold the weight of the dam – required workers called “high-scalers” who excavated the cliffs, dangling on ropes from the rim of the canyon. Can you even fathom this?

Consider the feat of building the monumental Hoover Dam (1931-1936) – a miracle of technology and engineering. No dam project of this scale had ever been attempted before. There were 21,000 people working at that site with approximately 100 industrial deaths. The walls for this structure – that would uphold the weight of the dam – required workers called “high-scalers” who excavated the cliffs, dangling on ropes from the rim of the canyon. Can you even fathom this? Consider the great Niagara Power Project (1957-1961). During construction, over 12 million cubic yards of rock were excavated. A total of 20 workers died. When it opened in 1961, it was the Western world’s largest hydropower facility. Many people, including from the “greatest generation” and the “traditionalist generation,” worked together on this project. It was a 24/7, multi-year project.

Consider the great Niagara Power Project (1957-1961). During construction, over 12 million cubic yards of rock were excavated. A total of 20 workers died. When it opened in 1961, it was the Western world’s largest hydropower facility. Many people, including from the “greatest generation” and the “traditionalist generation,” worked together on this project. It was a 24/7, multi-year project.