As I study the safety publications like Professional Safety and EHS Today, there is a lot of effort in discussing new ways to achieve better safety performance, develop better ways to do hazards investigations, evaluate accidents, and being in compliance with OSHA standards.

When I have attended American Society for Safety Professionals and American Institute of Chemical Engineers meetings and conferences, there are lots of papers focused on improving various aspects of safety for the people at work and being in compliance with OSHA standards. There are thousands of really good safety professionals doing this work.

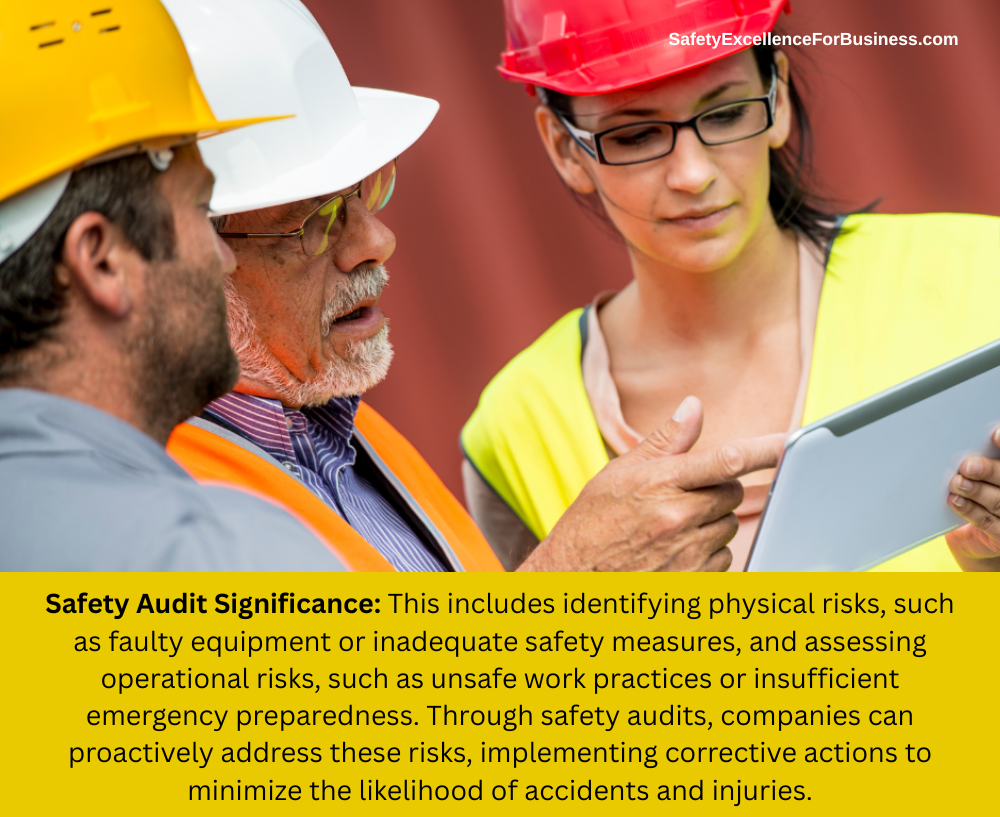

There is also a lot of effort in developing a better understanding of OSHA Standards and rules. There is good advice on how to work effectively with OSHA. None of us want to get OSHA citations after an audit.

I remember how nervous I was when we had our occasional OSHA audits. Most of the time we had successful audits (we had complied with the Standards), but now and then we’d get a citation which then brought down a lot of criticism from upper management. Being in compliance is really important from a career and publicity perspective, so we worked really hard to meet the OSHA Standards.

Surviving an OSHA investigation without any citations is one measure of success for safety professionals. I know that it takes a lot of work to have a successful audit.

Moving Beyond Compliance is Important

Another way to see how well we are doing is to look at the people getting injured or killed at work. This is not a numbers game; we are working with real people.

This is important to our companies since these tragedies can cost a lot of money for health care or have to deal with lawsuits. It can also cause bad publicity, prompt an OSHA investigation, and suffer fines, and destroy families.

Fortunately, most of the millions of businesses in the USA don’t have these problems, which gives them a feeling of success. They are in compliance. This can lull them into thinking they are doing a great safety job; then something happens and everything hits the fan.

Unfortunately, a lot of businesses do have fatalities (5,200 a year) and injuries (about 2,500,000 a year). We can’t predict which businesses will have a tragedy so many may think that it will not happen to us, and feel compliance is good enough. But compliance is not good enough, in my view. A death or serious injury are devastating to those involved and the families and loved ones never got over the loss, EVER!

A Path Forward

When I was managing operations where we could have a fatality or serious injury, I found that partnering with the people was extremely important.

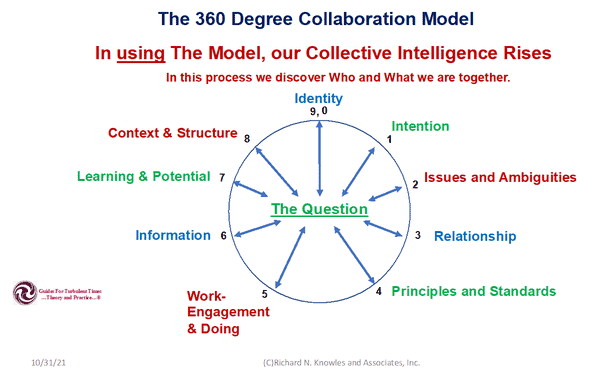

We created an environment where we could all talk together about work, share our ideas and insights freely, and learn together – all of us at all levels, contributed and shared our knowledge. contributed and learned. The collective knowledge of our organization grew and strengthened as we co-created our future. We treated each other with respect and care, maintained high standards, and addressed problems together.

As we learned together, more and more people began to contribute. We did not just work on safety – we worked on all aspects of our work.

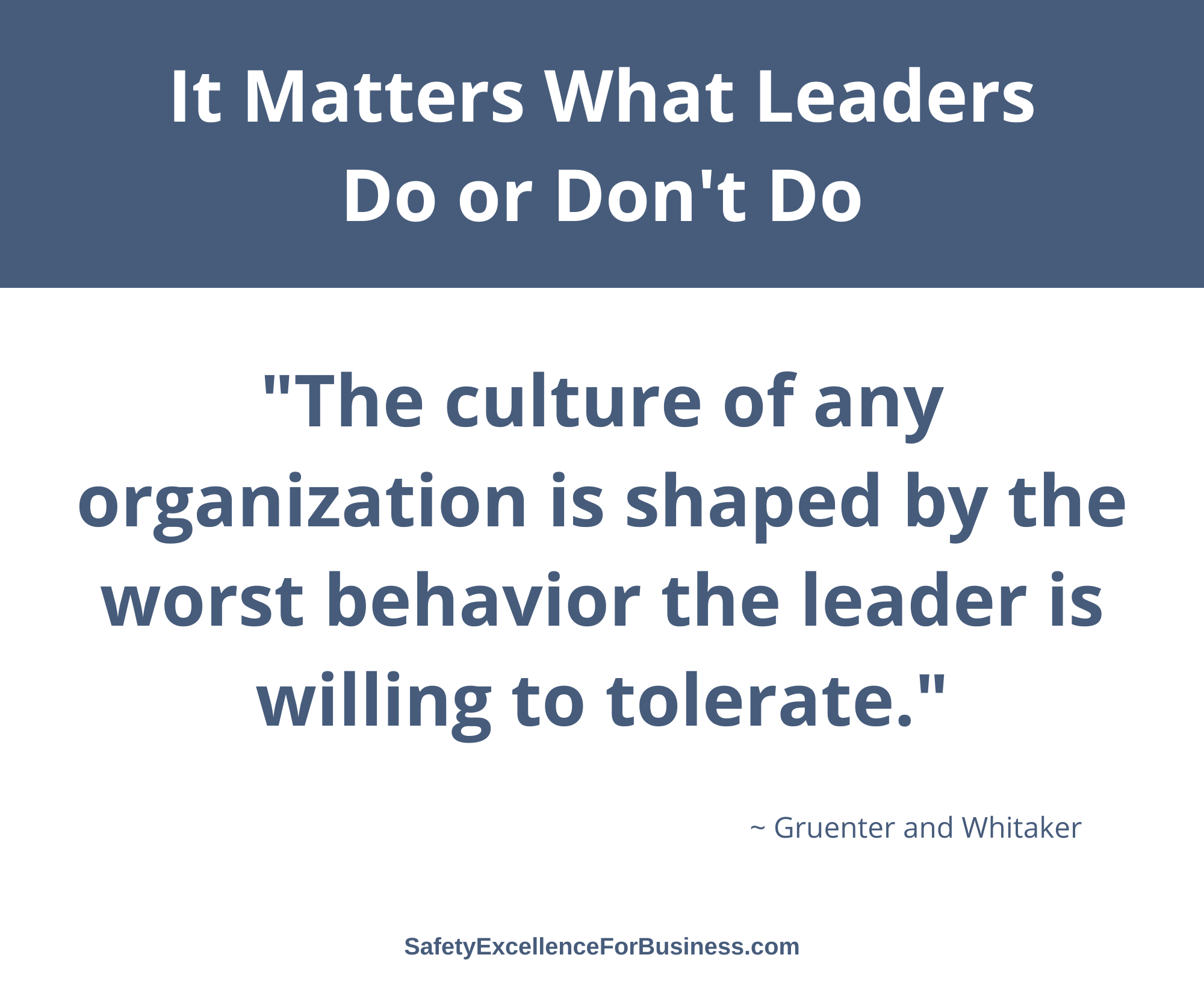

I spent about half of my time walking among the people in the plant, getting to know the people, and building our relationships and trust. I modeled how we needed to work together so people could see that I was genuinely interested and committed to improving all we did.

I had a safety mantra:

“I do not have the right to make my living at a place where it is okay for you to get hurt.

I can’t do this all by myself, so I need your help.

We also have to make a living, so we must work together to figure out how to do all this.”

Our total performance made significant progress, people were more satisfied, we had more fun, and my job got a lot easier as we focused on our growing successes.

I would be pleased to talk with you if you would like to do this. We could do this with a Zoom or phone call. Call me (716-622-6467) to set up a meeting.