It is a new year. Businesses have compiled their 2018 safety statistics. They are looking at economics and at people. Who was hurt during this past year? What have we put in place so that those injuries won’t happen again? What are we talking about together for betterment? How did our systems contribute to our successes or to the injurie/s? What was the presence and the strength of Leadership support like around those people who were injured? Where are we most vulnerable safety-wise? How can we lead more effectively? How can we have an even safer workplace in this new year, 2019? How can we help employees to become more aware, more safety vigilant? And thus more able to return to their families at the end of the shift whole – with arms, legs, toes, fingers, eyes, ears – all intact. (Leaders, are you asking these questions?)

It is a new year. Businesses have compiled their 2018 safety statistics. They are looking at economics and at people. Who was hurt during this past year? What have we put in place so that those injuries won’t happen again? What are we talking about together for betterment? How did our systems contribute to our successes or to the injurie/s? What was the presence and the strength of Leadership support like around those people who were injured? Where are we most vulnerable safety-wise? How can we lead more effectively? How can we have an even safer workplace in this new year, 2019? How can we help employees to become more aware, more safety vigilant? And thus more able to return to their families at the end of the shift whole – with arms, legs, toes, fingers, eyes, ears – all intact. (Leaders, are you asking these questions?)

I don’t believe anyone wakes up in the morning and then upon entering the workplace plans on getting hurt that day. Nope. It doesn’t work that way. Rather, we go into work, we start our work, and our focus tends to wander from safety – inattentiveness – hurrying – trying to do two things at once – perhaps even emotionally upset at times. The result is that slips, falls, pinches, pinnings, caught between, run over, cuts, scrapes, and near-misses or worse scenarios come about. Somehow we drop the ball on being able integrate safety into the whole task from the initial safety reminders to the safety wrap-up at the end of the day. Even in-your-face safety signage doesn’t save the day.

It doesn’t have to be that way. Nope. Safety starts when YOU—the individual person takes a stand that YOU will work safe…all day. YOU will ask yourself where the biggest risks are and how you must prepare for them. YOU will watch out (as well), for your buddy and the newbie. YOU are an adult. YOU don’t want to have to wear a brace or a cast or bandage because of the pain and the inconvenience it’ll cause you. YOU don’t want to have to miss work or become a statistic. YOU will look out for booby-traps and surprises. YOU will be attentive to what is happening around you and with your specific task. YOU will be your own poster child for doing your work safely…because YOU want to…because it is the right thing to do, because YOU can think for yourself. YOU don’t need to have a safety prize for a reward, either. YOU decide to be safe…everyday, every moment, every task, constantly building on the good things you know and strengths you have. YOU make the decision!

Why am I beating this drum today for this newsletter? Because it is a clear aspect of Safety and Leadership. Until YOU can take a stand…a genuine stand…on YOUR own Safety, your head won’t be or stay in the game. And Leaders, Supervisors, Managers, CEO’s, you need to take your stand, too. Your stake has to be clearly and visibly in the ground. Your people need to know that you’ve taken your stance on safety and expect the same of them.

What does “taking a stand mean?” It means that not only will you publicly share that you recognize that YOU believe that working safely is important and something you must do, but you are, in addition, willing to ask all those you work with, to kindly hold you accountable to that stand. Will you do that? What’s your stand?

That’s the difference that makes the difference!

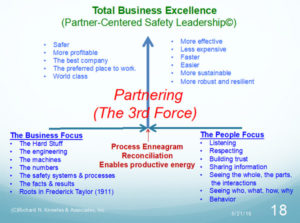

In our November Safety Newsletter, I wrote about Partner-Centered Leadership. This is the most effective way to improve safety performance. This way of leading also results in improvements in most other aspects of the business as trust and interdependence are built and the environment is safe for the open flow of information. A key aspect of this is working with the people.

In our November Safety Newsletter, I wrote about Partner-Centered Leadership. This is the most effective way to improve safety performance. This way of leading also results in improvements in most other aspects of the business as trust and interdependence are built and the environment is safe for the open flow of information. A key aspect of this is working with the people.

Leaders are people who have a vision of what is possible, are concerned and care enough to make a difference, have the courage and commitment to do the work, and truly engage with people to learn, grow and to achieve their results. These are people who regularly go into their organizations, walk around, have the important conversations about getting better, building a respectful workplace, listening carefully, building trust and interdependence, and helping the people to be the best they can be. They create environments where it is safe to openly talk together, ask questions, share information, think out-loud and build a better future.

Leaders are people who have a vision of what is possible, are concerned and care enough to make a difference, have the courage and commitment to do the work, and truly engage with people to learn, grow and to achieve their results. These are people who regularly go into their organizations, walk around, have the important conversations about getting better, building a respectful workplace, listening carefully, building trust and interdependence, and helping the people to be the best they can be. They create environments where it is safe to openly talk together, ask questions, share information, think out-loud and build a better future. Lots of managers talk about the need for organizations to change and improve. But as I talk with people, go to conferences and read the safety literature, I hardly ever encounter anyone leading this way. So many managers do not know what it means to lead.

Lots of managers talk about the need for organizations to change and improve. But as I talk with people, go to conferences and read the safety literature, I hardly ever encounter anyone leading this way. So many managers do not know what it means to lead. It is a problem across society in general and a big safety and HR problem in our organizations. In 2017, it is estimated that there were about 72,000 overdoses across the country. About 70% of businesses report that they have been impacted by this terrible problem. The National Safety Council reports that there are problems with poor prescription drug use, higher absenteeism, injuries, and accidents resulting from overdoses.

It is a problem across society in general and a big safety and HR problem in our organizations. In 2017, it is estimated that there were about 72,000 overdoses across the country. About 70% of businesses report that they have been impacted by this terrible problem. The National Safety Council reports that there are problems with poor prescription drug use, higher absenteeism, injuries, and accidents resulting from overdoses. Next, you need to reach out to the people with respect and offer to help them. Many people with drug problems believe no one cares, so reaching out to help would be a step forward.

Next, you need to reach out to the people with respect and offer to help them. Many people with drug problems believe no one cares, so reaching out to help would be a step forward.

The rapid growth of active shooter incidents was one of the main areas of concern. The FBI and other experts gave talks about this, with their main focus on the active shooter incident itself. Most active shooter situations are conducted by men. Most of these occur in places of business. There is no typical profile for these people who come from all walks of life.

The rapid growth of active shooter incidents was one of the main areas of concern. The FBI and other experts gave talks about this, with their main focus on the active shooter incident itself. Most active shooter situations are conducted by men. Most of these occur in places of business. There is no typical profile for these people who come from all walks of life.

The more people who are involved in thinking about, looking at and helping each other, the more likely that the organization’s safety performance will be outstanding. A key to having the people come together as partners in helping each other begins with respect. I think that most of us want to be treated respectfully and feel valued by each other; I know that I do. We all have jobs to do and our work quality and productivity need to be as good as we can do. We each need to be held to high standards and keep learning and growing in our knowledge and understanding. We can achieve this while treating each other respectfully, honestly sharing our knowledge and insights, asking for help when we need it, and giving a helping hand.

The more people who are involved in thinking about, looking at and helping each other, the more likely that the organization’s safety performance will be outstanding. A key to having the people come together as partners in helping each other begins with respect. I think that most of us want to be treated respectfully and feel valued by each other; I know that I do. We all have jobs to do and our work quality and productivity need to be as good as we can do. We each need to be held to high standards and keep learning and growing in our knowledge and understanding. We can achieve this while treating each other respectfully, honestly sharing our knowledge and insights, asking for help when we need it, and giving a helping hand. We help to knock down the walls that have grown up between people and groups so that the arguments and fighting stop and they learn to value and help each other. We help to drill holes in the silos of production, HR, maintenance, and finance so that people can talk to each other to get the information they need to do their jobs. We help to remove the barriers that are restricting the up and down flow of critical information, improving its accuracy, so the organization can function more easily. We help to remove the barriers between the people writing rules and procedures (the work-as-imagined) and those doing the front-line work (the work-as-done). We help people to see that most of the injuries and incidents are the result of patterns and processes that need improvement and shift away from a culture of blame and criticism.

We help to knock down the walls that have grown up between people and groups so that the arguments and fighting stop and they learn to value and help each other. We help to drill holes in the silos of production, HR, maintenance, and finance so that people can talk to each other to get the information they need to do their jobs. We help to remove the barriers that are restricting the up and down flow of critical information, improving its accuracy, so the organization can function more easily. We help to remove the barriers between the people writing rules and procedures (the work-as-imagined) and those doing the front-line work (the work-as-done). We help people to see that most of the injuries and incidents are the result of patterns and processes that need improvement and shift away from a culture of blame and criticism. Changes are coming fast and furious. President Trump is moving ahead on deregulations and removing barriers to improve our businesses, so we’ll probably see a lot of changes show up in our workplaces. Some will be positive and others will not. It is our responsibility to work together and make all these changes as good as possible.

Changes are coming fast and furious. President Trump is moving ahead on deregulations and removing barriers to improve our businesses, so we’ll probably see a lot of changes show up in our workplaces. Some will be positive and others will not. It is our responsibility to work together and make all these changes as good as possible. Almost every day I see people post on LinkedIn, engaging in awful safety practices. Some are so ridiculous that they could be funny – except that people are getting hurt. Some workers seem quite content to endanger their lives and co-workers seem to be so unaware of the risks around them – that it is unbelievable!

Almost every day I see people post on LinkedIn, engaging in awful safety practices. Some are so ridiculous that they could be funny – except that people are getting hurt. Some workers seem quite content to endanger their lives and co-workers seem to be so unaware of the risks around them – that it is unbelievable! A recent Gallup study conducted over several years, covering about 150 countries, revealed that only about 15% of the people were actively involved in their work and that another 15% were actively opposing their managers and supervisors. The other 70% must be just doing as little as possible and not helping or looking out for each other. We are better in the USA, but not by much.

A recent Gallup study conducted over several years, covering about 150 countries, revealed that only about 15% of the people were actively involved in their work and that another 15% were actively opposing their managers and supervisors. The other 70% must be just doing as little as possible and not helping or looking out for each other. We are better in the USA, but not by much. One of the most effective things that I did in stressful and changing times like these was to follow these three rules:

One of the most effective things that I did in stressful and changing times like these was to follow these three rules: There are three important things that everyone needs to do to help to keep the safety performance and productivity high:

There are three important things that everyone needs to do to help to keep the safety performance and productivity high: In your tool box meetings or shift start meetings, consider expanding your thinking to imagine how someone could get killed in work planned for the day. This is beyond what most groups do, but is an excellent way to prevent an unlikely tragedy. Talk together about how a fatality could happen. Even the most unlikely scenario will happen one day. Talk about what is in place that will prevent the fatality if the event should happen. Then ask yourselves if these preventative measures are good enough to really protect you. If not, then consider what you need to do so that you will be protected from being killed if the unlikely event should happen.

In your tool box meetings or shift start meetings, consider expanding your thinking to imagine how someone could get killed in work planned for the day. This is beyond what most groups do, but is an excellent way to prevent an unlikely tragedy. Talk together about how a fatality could happen. Even the most unlikely scenario will happen one day. Talk about what is in place that will prevent the fatality if the event should happen. Then ask yourselves if these preventative measures are good enough to really protect you. If not, then consider what you need to do so that you will be protected from being killed if the unlikely event should happen. A wicked question is one where it is so complex that there is no final answer. We work to the best solution we can, which works for some period of time, then we have to revisit it again as conditions change. (The wicked question keeps repeating, sometimes reminding us of a bad penny – that keeps showing up at inopportune times!)

A wicked question is one where it is so complex that there is no final answer. We work to the best solution we can, which works for some period of time, then we have to revisit it again as conditions change. (The wicked question keeps repeating, sometimes reminding us of a bad penny – that keeps showing up at inopportune times!) We need to approach this from the whole systems perspective since everything is connected to everything else. Experience shows that if we try to just fix one part of the system or another, we will wind up making other parts worse.

We need to approach this from the whole systems perspective since everything is connected to everything else. Experience shows that if we try to just fix one part of the system or another, we will wind up making other parts worse.