Many Thousands of People are Being Injured and Killed at Work

Many, many good, safety professionals are working to maintain and improve workplace safety. Yet the number of people losing their lives in our workplaces (in just 4 years) has increased from 4,836 in 2015 to 5,333 in 2019, based on the Bureau of Labor Statistics. From 2015 through 2019 there have been 25,746 people who have lost their lives at work. To put this into an alarming perspective, compare this to the losses in Afghanistan since 2001 (over twenty years) where there have been 3,592 allied forces who have been killed, based on Associated Press.

With all the effort put into improving safety performance in our workplaces, why have we not seen a reduction in the number of people being killed at work? New papers sharing improved ways to ‘improve workplace safety’ are presented at safety conferences by the American Society of Safety Professionals, the American Institute of Chemical Engineers’ Global Congress on Process Safety, and many smaller conferences as well as in publications in a variety of journals. The informational know-how is available!

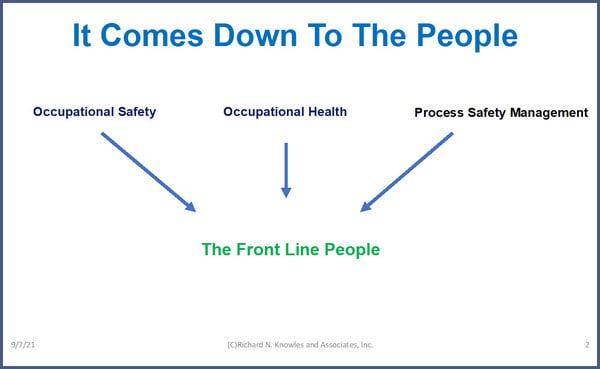

Each of the specialties of occupational safety, occupational health and process safety management have a huge amount of information that has been developed over the years to improve safety performance. While some progress has been made in reducing the total number of injuries from a rate of 3.0 in 2015 to 2.8 in 2019 (2,814,000 injuries) this seems slow to me.

What is Missing?

The fruits of all this work has to be carried out by the people actually doing the physical work, those close to the actual operating and maintenance processes. We need to help these people, and not just pile more stuff onto them.

I have found in all my 60 years in working in research, production and consulting globally that a missing link is not talking with the front-line people and exploring and learning together how to improve the work so that fewer injuries and incidents occur. None of us have all the answers. We need each other. (Talking down to people doesn’t work; talking to people (one-way) doesn’t work—the key is in talking with our people!)

Here is a Simple Solution…

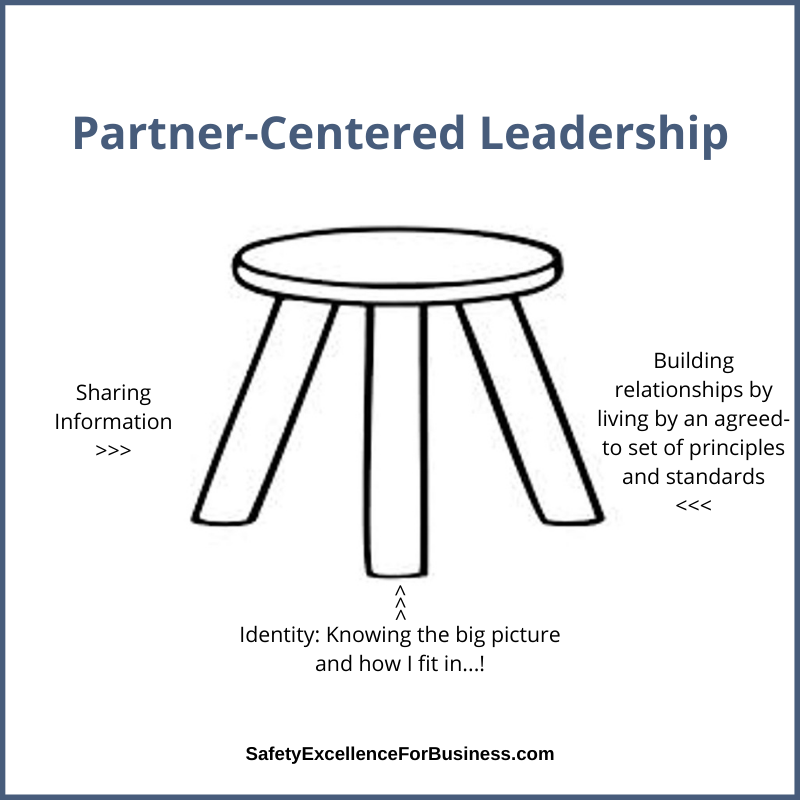

When I was the Plant Manager at the 1,300 person, DuPont Belle, WV Chemical Plant I changed this. In my leading process, I spent 4-5 hours a day for 7+years walking around in the Plant, being respectful, sharing information, listening, asking how I could help the people, asking them for their help, learning together to improve things and building trust and interdependence. I talked with everyone. My mantra was “I do not have a right to make my living at a place where it is okay for you to get hurt, and we have to make a living, so let’s figure this out together.”

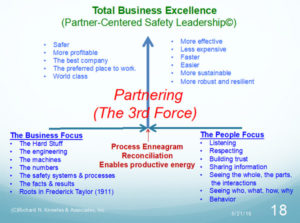

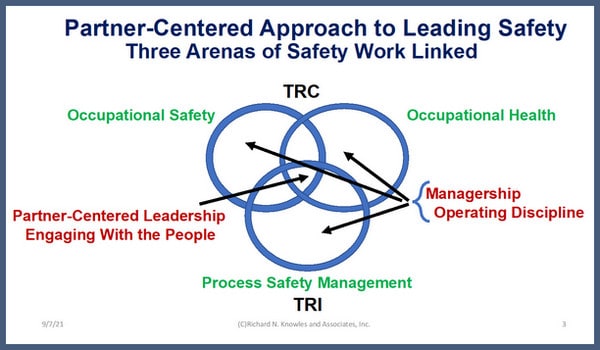

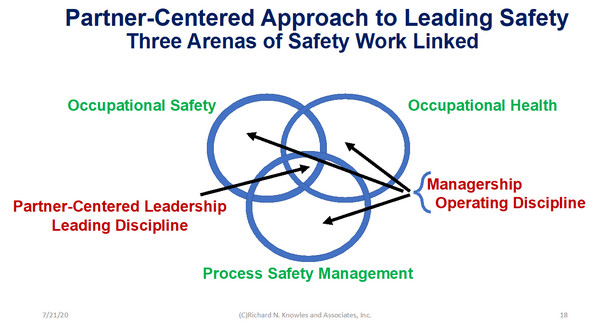

Our injury rate dropped by about 97% in three years, emissions to the environment dropped by about 96% in 4 years, productivity rose about 45% and earnings rose about 300%. Safety is connected to everything so as we made safety improvements everything else improved. In this approach which I call “Partner-Centered Leadership”, all parts of our safety work came together as shown here.

Each of occupational safety, health and process safety have their unique knowledge and management disciplines. When they are brought together, in the region of overlap in the center of this Venn Diagram, this is where the people and the leading process described above come together. In addition to talking with everyone about all the dimensions of our safety work as I walked around, there was one place where this all came together and was clear to everyone. Our monthly Central Safety Meetings were open, and all aspects of our safety work were discussed openly with everyone. All questions and concerns were welcome, and fixed. I strongly urged our supervisors to talk with their people and the engineers to sit with the operators to teach them the elements of process safety.

This is Simple.

Go into your workplaces, respectfully talk with the people, listen, share, ask them where you can be of more help, help them to follow up on their ideas and concerns, solve problems, build trust, and have everyone go home healthy and in one piece. Engagement!

You can do this!

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread.

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread. In this story, a wicked witch puts the princess and the whole kingdom to sleep for 100 years. They all have to wait for the arrival of the prince to kiss the princess and awaken everyone. As children, we all knew this story, but in this new book, Stephen Capizzano shifts the story to thinking about what happens in our organizations.

In this story, a wicked witch puts the princess and the whole kingdom to sleep for 100 years. They all have to wait for the arrival of the prince to kiss the princess and awaken everyone. As children, we all knew this story, but in this new book, Stephen Capizzano shifts the story to thinking about what happens in our organizations. When we were able to shed our old habits at our Plant in West Virginia, injury rates dropped by 97%, emissions to air, ground and water as reported to the EPA dropped 95%, productivity rose by 45% and earnings rose by 300%. As I walked the plant for 5 hours each day we were reminding ourselves to shed the old habits and create a much brighter future.

When we were able to shed our old habits at our Plant in West Virginia, injury rates dropped by 97%, emissions to air, ground and water as reported to the EPA dropped 95%, productivity rose by 45% and earnings rose by 300%. As I walked the plant for 5 hours each day we were reminding ourselves to shed the old habits and create a much brighter future. Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place.

Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place. When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed.

When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed. This begins with the leaders deciding to create a culture where it is okay and encouraged that people genuinely talk together, listen, help each other, look out for each other and learn together. This is a culture that helps people to be the best they can be and for the organization to get a lot more profitable. It all begins with all of us treating each other with respect.

This begins with the leaders deciding to create a culture where it is okay and encouraged that people genuinely talk together, listen, help each other, look out for each other and learn together. This is a culture that helps people to be the best they can be and for the organization to get a lot more profitable. It all begins with all of us treating each other with respect. This is the sort of culture that Eric Hollnagel is talking about in his Safety II work, which is intended to move the organization beyond the traditional top-down safety management. (I’ve written about Safety II in previous articles – it is all good!)

This is the sort of culture that Eric Hollnagel is talking about in his Safety II work, which is intended to move the organization beyond the traditional top-down safety management. (I’ve written about Safety II in previous articles – it is all good!)

In our November Safety Newsletter, I wrote about Partner-Centered Leadership. This is the most effective way to improve safety performance. This way of leading also results in improvements in most other aspects of the business as trust and interdependence are built and the environment is safe for the open flow of information. A key aspect of this is working with the people.

In our November Safety Newsletter, I wrote about Partner-Centered Leadership. This is the most effective way to improve safety performance. This way of leading also results in improvements in most other aspects of the business as trust and interdependence are built and the environment is safe for the open flow of information. A key aspect of this is working with the people.