Why Process Safety Management is needed and everyone needs to be Involved!

Week after week I read of explosions and fires at refineries, chemical plants and dust-producing operations like sawmills and grain elevators. There are usually people hurt or killed. Communities are forced to shelter in place or evacuate. Families suffer great loss. There are always estimates of the loss of money and the difficulty of getting back into production.

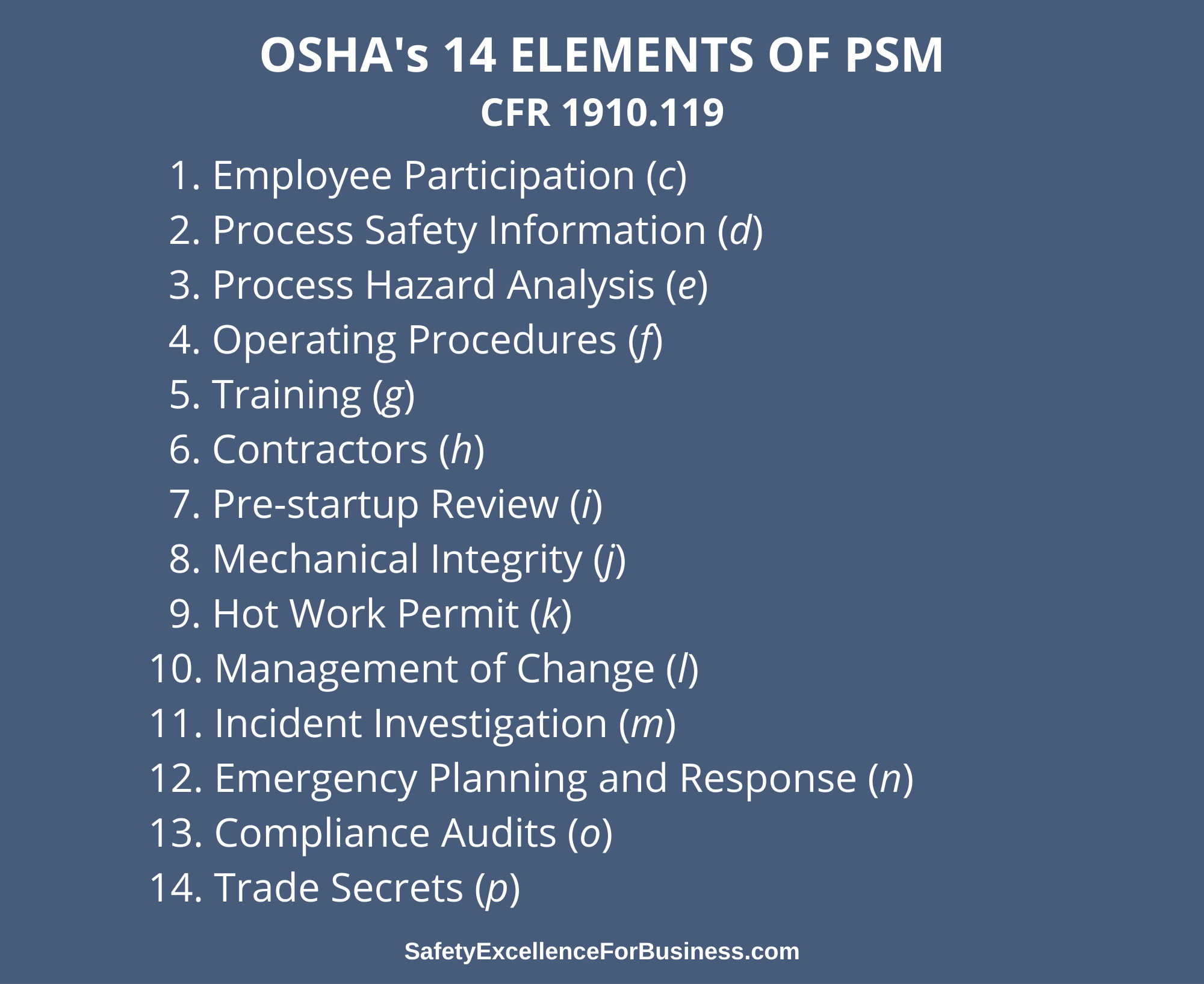

These are sad situations that are usually avoidable if the managers and engineers would only do their duty to conduct strong process safety management (PSM) work. PSM does require having trained engineers to do the work. It may require money when a defect is found the needs repair. It is often routine and boring work as in inspecting relief valves, for example. It often is narrowly focused on just the specific process without taking the whole system into mind. This is critical work that responsible managers and engineers need to conduct rigorously. It is a necessary discipline. (Process Safety Management came about as OSHA’s response to prevent a disaster like Bhopal).

When I read the reports of these disasters, there are often long explanations about things. There was one I read about where the fluctuating liquid levels in distillation columns were unstable and causing the operators continuous problems. The instruments were not showing the full nature of the problem of the rising liquid levels which, one day, got so out of control that the distillation column overflowed, releasing a flammable cloud which ignited and killed a lot of people. The incident investigation discussed all sorts of technical problems which were not addressed since they did not look too serious. But they did not include the whole system.

Nowhere was there any discussion mentioned about what the operators were experiencing each day and struggling to control. It was clear that they had a serious problem, but no one asked them about it. Why do the technical people treat the men and women who operate the facilities as if they did not know anything. These people live with the processes! They have a lot to offer!

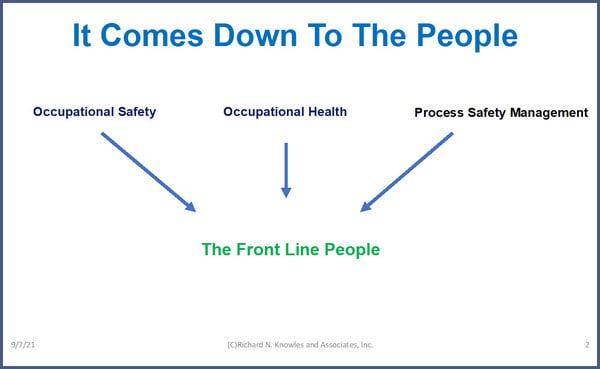

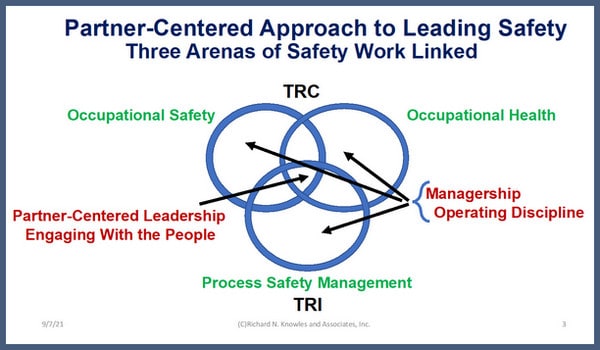

When I was the Plant Manager of the big DuPont Belle, West Virginia plant, we brought occupational safety, occupational health, and PSM together as a whole safety system effort where each part helped the other parts. We created the conditions where people felt it was okay to talk openly together about the problems and address them. Where they helped each other. Trust was built so people could be able to do their best. The people came together enabling us all to perform much better.

Our Total Recordable Injury rate dropped by 97% to ~0.3 and our total emissions to the environment dropped by 95% in just 3 years. I look at total emissions to the environment as a key PSM metric since there is less waste from poorly running processes and fewer upsets or failures blowing stuff into the air.

Building trust and interdependence among the people is a very important part of management’s work. It is easy to do this using the Cycle of Intelligence, listening and learning together. Rosa Carrillo has written a fine book about the importance of the Relationship Factor entitled “The Relationship Factor in Safety Leadership.” This is easy to do if we just go into our organizations, share information, listen, and learn together. It would have avoided the disaster I mentioned earlier in this newsletter.

Yet most managers do not get out of their offices, talk with the people sharing information, listening, and learning together. Why is this? Rosa’s work and my work clearly show the great benefits to safety and productivity, yet managers shy away from this.

WHY????

In your own organization, what are you doing to open up and share information? What are you doing to open up a safe space where it is okay for people to talk and share? Are you bringing a diverse group of people together to talk and learn?

Each of us can make a positive difference. Will you?

In this story, a wicked witch puts the princess and the whole kingdom to sleep for 100 years. They all have to wait for the arrival of the prince to kiss the princess and awaken everyone. As children, we all knew this story, but in this new book, Stephen Capizzano shifts the story to thinking about what happens in our organizations.

In this story, a wicked witch puts the princess and the whole kingdom to sleep for 100 years. They all have to wait for the arrival of the prince to kiss the princess and awaken everyone. As children, we all knew this story, but in this new book, Stephen Capizzano shifts the story to thinking about what happens in our organizations. When we were able to shed our old habits at our Plant in West Virginia, injury rates dropped by 97%, emissions to air, ground and water as reported to the EPA dropped 95%, productivity rose by 45% and earnings rose by 300%. As I walked the plant for 5 hours each day we were reminding ourselves to shed the old habits and create a much brighter future.

When we were able to shed our old habits at our Plant in West Virginia, injury rates dropped by 97%, emissions to air, ground and water as reported to the EPA dropped 95%, productivity rose by 45% and earnings rose by 300%. As I walked the plant for 5 hours each day we were reminding ourselves to shed the old habits and create a much brighter future.

The COVID-19 pandemic, the return to school questions, the protests and riots in so many of our cities, the bitter political campaign, the demand for using the “correct” words, are driving people crazy. The COVID-19, the questions, the anxieties and concerns, spill into our workplaces causing a lot of uncertainty and stress. We see this happening every day. Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are struggling. Changes and pressures are coming faster and faster.

The COVID-19 pandemic, the return to school questions, the protests and riots in so many of our cities, the bitter political campaign, the demand for using the “correct” words, are driving people crazy. The COVID-19, the questions, the anxieties and concerns, spill into our workplaces causing a lot of uncertainty and stress. We see this happening every day. Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are struggling. Changes and pressures are coming faster and faster. In thinking about your own place where you work, what do you suppose it would be like if you did some of these things? Do you think that you could begin talking with others about the COVID-19 challenges and building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like workable, social distancing and improving the safety of your job?

In thinking about your own place where you work, what do you suppose it would be like if you did some of these things? Do you think that you could begin talking with others about the COVID-19 challenges and building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like workable, social distancing and improving the safety of your job? When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment.

When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment. The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen.

The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen. You can’t turn on the news or check your Internet homepage without sensing the depth of the issues that our country is experiencing. Whether it is returning to the workplace amidst COVID-19 rules, political protests, religious non-tolerance, or negative nightly news events – we’re experiencing a wide berth of dramatic events. And each of us has an opinion, a response, a way that we individually see these events and cope with this discord.

You can’t turn on the news or check your Internet homepage without sensing the depth of the issues that our country is experiencing. Whether it is returning to the workplace amidst COVID-19 rules, political protests, religious non-tolerance, or negative nightly news events – we’re experiencing a wide berth of dramatic events. And each of us has an opinion, a response, a way that we individually see these events and cope with this discord. It doesn’t have to be that way! Take a timeout!

It doesn’t have to be that way! Take a timeout! The pain and suffering is miserable.

The pain and suffering is miserable. Changes are coming fast and furious. Everything seems to be changing all around us. This can cause unsettling feelings and a loss of control. However, in the middle of all this change, one area that can be steady for us is our relationships with each other.

Changes are coming fast and furious. Everything seems to be changing all around us. This can cause unsettling feelings and a loss of control. However, in the middle of all this change, one area that can be steady for us is our relationships with each other. Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place.

Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place. When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed.

When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed. There have been five fatalities since the project began. All five of the fatalities have been “struck-by” incidents. The most recent occurred about October 1st, when a beam slipped off a piece of equipment and struck a worker on the head. One person was hit by a dump truck. Another died when he was hit by a piece of steel equipment. The fourth person died when a rebar cage fell on him, and the fifth person was killed when he was hit in the head by a pipe.

There have been five fatalities since the project began. All five of the fatalities have been “struck-by” incidents. The most recent occurred about October 1st, when a beam slipped off a piece of equipment and struck a worker on the head. One person was hit by a dump truck. Another died when he was hit by a piece of steel equipment. The fourth person died when a rebar cage fell on him, and the fifth person was killed when he was hit in the head by a pipe.