But What Does Every Employee Want from their Managers/Leaders? And, How Do We Get These, Together?

In a 2017 article in INC online magazine, the desired universal list of what every manager looks for in an employee was highlighted:

- Predictable results (get stuff done – be counted on to deliver!)

- Drama-free collaboration (play well in the sandbox; don’t cause interpersonal issues)

- Spontaneous initiative (don’t expect to be told exactly what to do every time)

- Truth-telling (candid about issues; willing to speak up, diplomatic)

- Enthusiasm (show your positive engagement)

- Continuous growth (treat your job as part of career)

But what does every employee (universally-speaking) want as traits in their managers/leaders (excerpts from the SESCO Survey report)?:

- Honesty. 90% say they want honesty and integrity from their manager. Lies and secrets are the biggest killers to credibility.

- Fairness. 89% want their manager to be fair and to hold all employees accountable to the same standards.

- Trust. More than 86% want to trust-and be trusted by-their manager.

- Respect. 84% want to respect-and be respected by-their manager.

- Dependability. 81% say they want to be able to count on their manager when needed.

- Collaboration. 77% want to be a part of their manager’s team and be asked to contribute ideas and solutions. Shutting employees out will shut them up-and send them shipping out.

- Genuineness. 76% want their manager to be a genuine person. Employees sometimes spend more time with their boss than with their families-they don’t want a phony.

- Appreciation. 74% want their manager to appreciate them for who they are and what they do. When was the last time you handed out a “Thank you!” or “Great job!” to employees?

- Responsiveness. 74% want their manager to listen, understand and respond. Be a sponge, not a brick wall.

I share all this because, if you follow my work with the Process Enneagram©, you can pick up very quickly that there are certain things that are integral to each point of that framework – especially the pattern for excellence that I call Partner-centered Leadership©.

I share all this because, if you follow my work with the Process Enneagram©, you can pick up very quickly that there are certain things that are integral to each point of that framework – especially the pattern for excellence that I call Partner-centered Leadership©.

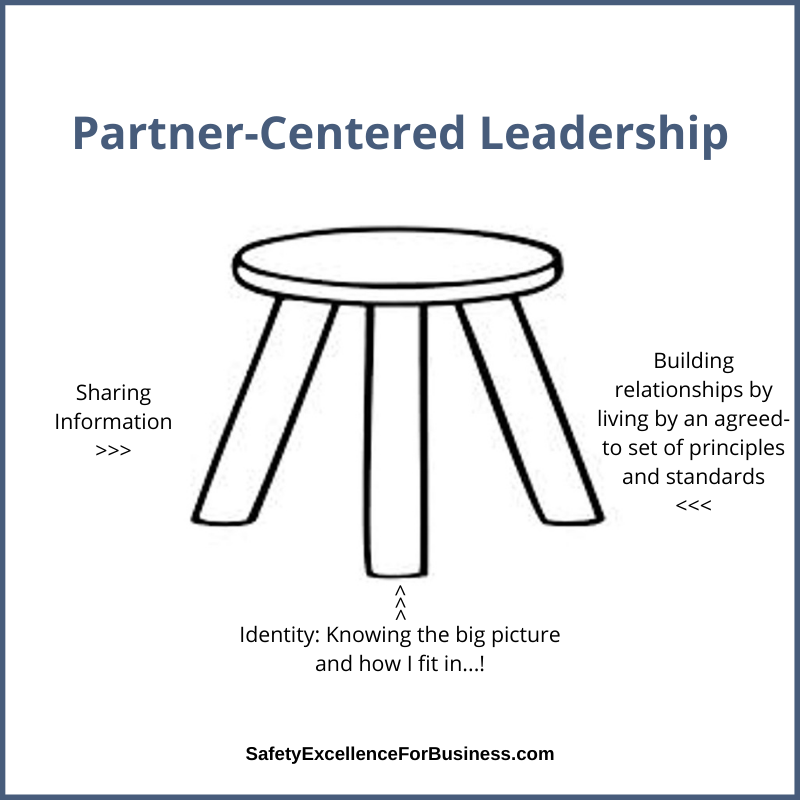

Particularly, the qualities that employees want from their managers (and their coworkers) fall into the Building of Relationships by living by agreed-to Principles and Standards – essential ingredients: Honesty, Fairness, Trust, Respect, Dependability, Collaboration, Genuineness, Appreciation and Responsiveness. This is how we choose to behave with and treat each other!

Employees want sufficient information to be able to do their jobs and to understand how they fit in the big picture. Each cog in the wheel is essential. Yet they also need to understand where that wheel is rolling, what direction, and how fast. They do not want to be jerked around.

Information-sharing & Identity/Frame of Reference: Employees want the truth about the business…where does it stand? What is needed to move forward? What is required performance-wise for the next quarter? What is in it for me? How can I grow as the business succeeds? These are valid questions. How do I fit in to our success (likened to the stonecutter who was building a cathedral!)?

Leaders / Managers / Employees …Yes, you can get it all…together! Call me at 716-622-6467 and I’ll share the process with you. We teach Leaders and Managers how to do this, and we train-the-trainers too – so that you can have sustainability.

These three legs on the 3-legged stool are essential: Living by a set of Principles and Standards so that you can Build Relationships, Sharing Information, and Ensuring a Sense of Identity. Why? Because all things get done through people. And People Matter! And these are the ingredients for a successful business.

The key features for leaders/managers to remember in Partner-Centered Leadership are:

- Valuing people, change and the future

- Seeing organizations as if they are living systems

- Recognizing organizations as complex, adapting, self-organizing networks of people

- Focusing on the open flow of information, building respect and trust

- Helping people to find meaning in the work itself

Partner-centered Leadership | Safety Excellence For Business

When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment.

When I was transferred to the DuPont Belle, West Virginia plant in 1987, the Total Recordable Injury Case Rate (TRC) was about 5.8 and emissions to air, water and ground, as reported in the EPA Toxic Release Inventory (TRI) annual report, was over 6,000,000 pounds/year. Within three years, both of these had dropped by about 95% to a TRC of about 0.3 and a TRI of about 275,000 pounds/year. Emissions to the environment is one way to measure how well the process safety is working; the better the process safety work, the lower the emissions to the environment. The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen.

The process safety management collapsed in January of 2010 with major, accidental releases to the air and river and they had a man get killed with a phosgene release. When the US Chemical Safety Board investigated in late 2010, they reported that while the occupational safety and health performance was the best in the DuPont Company, the process safety management had fallen apart and the plant was not even using the DuPont standard procedures. This was a sad commentary about how far things had fallen. Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place.

Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place. When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed.

When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed.