Violence in the workplace is a costly, unnecessary, largely preventable problem. It shows up as incivilities, bullying, sexual harassment, vengeful actions, and sometimes as homicides. These dysfunctional behaviors are costing businesses and the people working for them a lot of money and suffering.

According to the Bureau of Labor Statics Census of Fatal Occupational Injuries, there were 403 workplace homicides in 2014 out of a total of about 4,700 workplace fatalities. Almost two million harassment incidents are reported to OSHA each year, and while there is guidance to thwart them, there are no OSHA Standards dealing directly with this problem. There is, however, the General Duty Clause requiring employers to provide a safe workplace, and it has been noted that this includes physical safety and psychological safety.

Each time I see the scroll come across the bottom of the TV screen, or read an online news report of the main points of the day, I cringe when it relates to another occurrence of a workplace violence incident and tragedy. We know it is preventable. It doesn’t have to be that way.

Call us at 716-622-6467 and let’s discuss your concerns in this arena!

Pertinent Questions

What does an engaged, satisfying workplace look like?

Many surveys indicate that almost 70% of the people in our workforce are unhappy with their work situation. Are these people putting in their best efforts to make the safety of their place any better or help to solve customer problems quickly or reaching out in a caring way to help one of their work mates who may be having a problem?

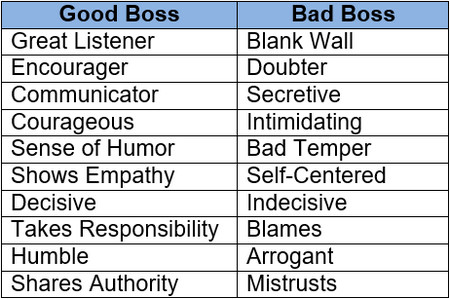

What should owners, managers and supervisors be doing?

Owners, managers and supervisors have many things they can do to make their organizations safer and more humane, and to increase positive engagement. It begins with these people in leadership positions recognizing and owning the problem. Thorough pre-hiring investigations and careful screening of supervisory candidates are necessary. Strong policies and training about workplace violence are needed. Terms like bullying need clear definitions. Clear, widely shared standards of behavioral expectations are required. Follow-up by all levels of management is necessary to be sure that everyone is doing their best to build a more humane and productive workplace.

What is particularly required of supervisors and managers?

Supervisors need training on how to be fully aware of what is happening with their direct reports…(Do they know their people?) and are they able to hold the important, sometimes difficult conversations with their reports to address and head-off problems before they get out-of-hand? As people talk together about these problems in an atmosphere of trust and caring, everything in the business will improve. We have seen all aspects of performance go up 30-40% when the people can work together like this…when they are able to lift up the elephants (including the psychological ones) that get in the way of the team or work group from being the best that it can be (together).

Some recent, heart-wrenching examples:

Here is a current example of a situation that was reported in the Washington Post where everything was missing. The recent killing by Radee Prince of three people in Edgewood, Maryland and another in Wilmington, Delaware on October 18th is a case where all the things described above were missing. He had a record of 42 arrests, including 15 felony convictions, but did anyone look? Why was he hired? He bullied his co-workers so much that a peace order (like a restraining order) was sought but denied by a judge because it did not meet the burden of proof. People had complained about him to management, but Prince was deemed to “be a good worker.” Where were the supervisors and others to support the claim of fearful concern by coworkers? He was eventually fired but returned to the workplace a number of times threatening other employees. Who let him in? This mess was costly, preventable and so sad!

In another example, on October 20th, in a Ford Stamping Plant in Detroit, police were called when a 21 year old, part-time employee was reported to have a gun in the plant. When he was found and confronted, he shot himself. Didn’t anyone notice that this person was not behaving well? Did anyone know and care about him? Was the EAP person invited in to consider coaching this person? His whole world had collapsed around him and no one noticed?

Helping to reduce workplace violence is work that all of us can do and have a part in. Let’s all pull together to help each other. Do we all care enough?

Are you cringing right now, because you think that having a comprehensive Workplace Violence Prevention Program (policy, training, vulnerability assessment) means too much work?

Think again.

The more fully engaged your people, supervisors and managers are, the better your workplace will be on many levels. The more “aware” of what is happening around you and the more able you are to have open dialog about this changing world of work – including the psychological and physical aspects of your workplace – the better off everyone will be, including the bottom line. (Give us a call. We can help you through this!)

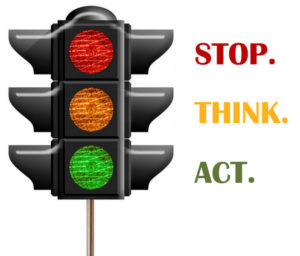

Violence at work is a growing problem. Shootings are becoming one of the leading causes of workplace deaths. Many organizations are having the local law enforcement people come in and do active shooter programs. This is a start. Preventing workplace violence has several aspects and becoming aware of how vulnerable your workplace may be, requires a physical-safety and psychological-safety assessment. These problems just don’t happen overnight in most cases. When someone is struggling with a serious problem at home or at work and have to just keep it to themselves, they get more and more lonely and resentful. If they are subjected to bullying and harassment things get bad, quickly. Stuff can build up to a tragedy. (How well do your supervisors know their people?)

Violence at work is a growing problem. Shootings are becoming one of the leading causes of workplace deaths. Many organizations are having the local law enforcement people come in and do active shooter programs. This is a start. Preventing workplace violence has several aspects and becoming aware of how vulnerable your workplace may be, requires a physical-safety and psychological-safety assessment. These problems just don’t happen overnight in most cases. When someone is struggling with a serious problem at home or at work and have to just keep it to themselves, they get more and more lonely and resentful. If they are subjected to bullying and harassment things get bad, quickly. Stuff can build up to a tragedy. (How well do your supervisors know their people?) As I travel around and watch things happening, I see so many people in a big hurry. We are coming to the end of the good weather so people are hurrying to get outside jobs finished up. Roofers are really busy and not taking the time to properly use and secure their fall protection. I read of a recent 29-story fall in New York City when a guy on a big construction site fell through an unsecured hole in the floor.

As I travel around and watch things happening, I see so many people in a big hurry. We are coming to the end of the good weather so people are hurrying to get outside jobs finished up. Roofers are really busy and not taking the time to properly use and secure their fall protection. I read of a recent 29-story fall in New York City when a guy on a big construction site fell through an unsecured hole in the floor. A good, proven approach is to have brief start up meetings to review the hazards of the day’s work, making sure we have the right PPE and other equipment in place and used, asking each other about what might go wrong and working to avoid this. We need to look over the schedules and be sure we have the equipment we need and the right people for the work.

A good, proven approach is to have brief start up meetings to review the hazards of the day’s work, making sure we have the right PPE and other equipment in place and used, asking each other about what might go wrong and working to avoid this. We need to look over the schedules and be sure we have the equipment we need and the right people for the work. Changes in our workplaces keep coming fast and furiously. A recent report released by Price-Waterhouse-Coopers indicates that by 2030 the pressure on workers to perform will be huge. Organizations will be using all sorts of ways to track performance…even putting chips under their workers skin to look at location, performance, health and wellness! They may be tracking safety performance as well. Managers will need to be having “mature conversations” with the people about all this change and the feeling of threat this creates for their people and their jobs. The pressure to keep improving skills and performance continues to increase.

Changes in our workplaces keep coming fast and furiously. A recent report released by Price-Waterhouse-Coopers indicates that by 2030 the pressure on workers to perform will be huge. Organizations will be using all sorts of ways to track performance…even putting chips under their workers skin to look at location, performance, health and wellness! They may be tracking safety performance as well. Managers will need to be having “mature conversations” with the people about all this change and the feeling of threat this creates for their people and their jobs. The pressure to keep improving skills and performance continues to increase.

Employee engagement has long been a concern to the U.S. workforce…it is a vital component of employee attraction and retention. Yet, with all the leadership programs targeted to “engage better with employees,” there hasn’t been a significant shift in relationships.

Employee engagement has long been a concern to the U.S. workforce…it is a vital component of employee attraction and retention. Yet, with all the leadership programs targeted to “engage better with employees,” there hasn’t been a significant shift in relationships. I just saw an announcement that the Liberty Mutual Research Institute for Safety was closing after 59 years, to reduce costs. The ISO 45001 Standard is in the final stages and is aimed at improving safety around the world. Yet some people are reacting that it will not make a difference because of management indifference or cost restraints.

I just saw an announcement that the Liberty Mutual Research Institute for Safety was closing after 59 years, to reduce costs. The ISO 45001 Standard is in the final stages and is aimed at improving safety around the world. Yet some people are reacting that it will not make a difference because of management indifference or cost restraints. Many of you who have been reading this newsletter know that our emphasis is on Partner Centered Leadership. We emphasize the importance of supervisors and managers getting into their workplaces each day and talking with the people. Talking with the people is a key to breaking through to safety excellence. Talking about the risks they face each day, how they are managing them, how their kids are doing, how the safety is doing, how the business is doing, asking them what they see as to ways to improve their own work, asking about problems they are dealing with, etc. Doing this with respect and really listening are vitally important.

Many of you who have been reading this newsletter know that our emphasis is on Partner Centered Leadership. We emphasize the importance of supervisors and managers getting into their workplaces each day and talking with the people. Talking with the people is a key to breaking through to safety excellence. Talking about the risks they face each day, how they are managing them, how their kids are doing, how the safety is doing, how the business is doing, asking them what they see as to ways to improve their own work, asking about problems they are dealing with, etc. Doing this with respect and really listening are vitally important. The American Society for Safety Engineers (soon to be The American Society for Safety Professionals) in Denver, Colorado, on June 19-22, 2017, was attended by about 5,000 people. This was a record for attendance. There were lots of papers and a huge trade show exhibit. I never saw so much safety equipment and other offerings.

The American Society for Safety Engineers (soon to be The American Society for Safety Professionals) in Denver, Colorado, on June 19-22, 2017, was attended by about 5,000 people. This was a record for attendance. There were lots of papers and a huge trade show exhibit. I never saw so much safety equipment and other offerings.

I love talking with people and getting to know them. Sometimes it is really interesting and sometimes it gets quite funny. The other night I was at the local piano bar, sitting between two older gentlemen. One was an 86-year-old retired colonel who was pretending to play his imaginary drums along with the piano player and the other guy introduced himself to me 5 times in the first 10 minutes. Sometimes you just don’t know until you start talking.

I love talking with people and getting to know them. Sometimes it is really interesting and sometimes it gets quite funny. The other night I was at the local piano bar, sitting between two older gentlemen. One was an 86-year-old retired colonel who was pretending to play his imaginary drums along with the piano player and the other guy introduced himself to me 5 times in the first 10 minutes. Sometimes you just don’t know until you start talking. Hardly any of us can do our best work all by ourselves.

Hardly any of us can do our best work all by ourselves.