As this year comes to an end, we will be looking at our overall performance to see how we did and to plan for 2017. We will usually look at our injury statistics like the total recordable injury rate and try to determine how we performed. Often quite independently, others will look at other performance indicators to see how they came out. We act as if these are independent of each other, but in our organizations everything is connected so all aspects of performance influence each other. Everything happens through the people. All the parts are interconnected. Excellence in safety performance is strongly related to our total performance because it all works through the will of the people.

As this year comes to an end, we will be looking at our overall performance to see how we did and to plan for 2017. We will usually look at our injury statistics like the total recordable injury rate and try to determine how we performed. Often quite independently, others will look at other performance indicators to see how they came out. We act as if these are independent of each other, but in our organizations everything is connected so all aspects of performance influence each other. Everything happens through the people. All the parts are interconnected. Excellence in safety performance is strongly related to our total performance because it all works through the will of the people.

We traditionally try to apply safety and other metrics to our organizations in a machine-like fashion. We see that something needs to improve so we push harder as if we are pushing a wagon up hill. Too many regulators and managers sit in their offices trying to imagine what needs to be done and write a new procedure or rule so that things will be better. Then they issue edicts pushing everyone harder. However, the work as imagined is never the same as the work as done. Why do managers think that sitting, bound to their office chairs, that they know everything? How can they? Then at the end of 2017 we will do this all over again trying to understand why things did not get better. Around and around we go!

We break this vicious cycle by opening up ourselves to a different way of thinking, seeing and being.

Work-as-imagined and work-as-done are ideas developed by Erik Hollnagel in his book, Safety-I and Safety-II (2014. Ashgate Publishing Ltd., UK). Safety I is our traditional top-down management approach to safety management where rules and procedures are issued by those far from the actual work. This is like the approach discussed in the proceeding paragraph. I think that a lot of people are trying to do good safety work from the Safety I perspective, but the results are not improving fast enough.

Work-as-imagined and work-as-done are ideas developed by Erik Hollnagel in his book, Safety-I and Safety-II (2014. Ashgate Publishing Ltd., UK). Safety I is our traditional top-down management approach to safety management where rules and procedures are issued by those far from the actual work. This is like the approach discussed in the proceeding paragraph. I think that a lot of people are trying to do good safety work from the Safety I perspective, but the results are not improving fast enough.

For example, the Bureau of Labor Statistics (BLS) recently reported that the rate for nonfatal injuries and illnesses per 100 people dropped to 3.0 in 2015 from 3.2 in 2014 and 3.3 in 2013. That is a 10% drop over three years. That is way too slow! In 2015 2,900,000 injuries were reported. That is WAY TOO MANY people getting hurt. In an earlier paper the BLS reported that the number of fatalities has hovered around 4,700 people a year for the last 5 years. This is WAY TOO MANY!

This is not just a US problem. For example, Worksafe, New Zealand recently reported that the health and safety laws have had little effect on reducing fatalities further.

While driving safety from the top has had benefits historically, the effort is having less and less impact. But when we change our approach to working with the people to co-create our future, things change for the better quite quickly. This is true! It’s proven!

In the work of Richard N. Knowles and Associates, we approach the organization as if it is a living organism. Time after time coming out of our Safety Excellence Workshops, the performance improves quickly. When we engage with the people this way and help them to co-create their safety future, building on the positive strengths of the people, safety and all other aspects of their work get better quickly. For example, when I was the Plant Manager at the DuPont Belle Plant in West Virginia we worked this way, and our injury rates dropped by over 95% and earnings rose 300% in just three years. This is similar to Hollnagel’s Safety II approach.

Whenever we, at Richard N. Knowles Associates, work in organizations the safety and total performance improves quickly. Everything happens through the force of the will of the people. We release this force helping the people to co-create their shared future. Then we show them how to sustain their work for the years ahead. All dimensions of the business improve; costs are lower, productivity is higher, morale is better and far more people are working safely.

Call us at 716-622-6467 so you can release the positive, creative forces in your organizations quickly!

A recent article in the October 13, 2016

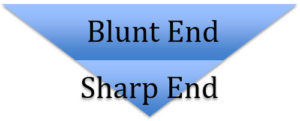

A recent article in the October 13, 2016  This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen. In many of our newsletters, I have talked about helping organizations co-create their safety future using the

In many of our newsletters, I have talked about helping organizations co-create their safety future using the  There was a video on Facebook a few weeks ago about Buddy Benches being placed in schoolyards. The video explained the importance of the communication and training that is essential to their use and effectiveness.

There was a video on Facebook a few weeks ago about Buddy Benches being placed in schoolyards. The video explained the importance of the communication and training that is essential to their use and effectiveness. On December 16-18, 2015, I was able to attend the Cruise Line International Association Safety Conference in Miami. The focus was on improving the safety culture and Bridge Resource Management. This is a very interesting business for me to learn about. I was there to give some perspective from the chemical industry.

On December 16-18, 2015, I was able to attend the Cruise Line International Association Safety Conference in Miami. The focus was on improving the safety culture and Bridge Resource Management. This is a very interesting business for me to learn about. I was there to give some perspective from the chemical industry. There is a big need to be sure the managers of chemical plants are qualified so that their employees and neighboring communities do not suffer the consequences of chemical releases and spills. Many manufacturing businesses that do hazardous work, aside from chemical manufacturing, should heed this thinking too.

There is a big need to be sure the managers of chemical plants are qualified so that their employees and neighboring communities do not suffer the consequences of chemical releases and spills. Many manufacturing businesses that do hazardous work, aside from chemical manufacturing, should heed this thinking too. I’m reminded about the organization that thought their safety performance was always good, because they were primarily an office environment. They scoffed over how bad could a paper cut be? Or, what’s the worst that could happen if someone fell off their chair? Little did they expect that one of their office workers, when on a healthy outdoor walk during her scheduled break time, tripped over some roped off tape that had been blown by the wind. She actually walked into it – not paying attention to her surroundings – got caught up in it as it wrapped about her feet. She fell, twisted her knee, required surgical repair, etc., etc. Try to explain that office worker lost-time injury! (The good: healthy walk; The bad: not paying attention; The ugly: lost time injury).

I’m reminded about the organization that thought their safety performance was always good, because they were primarily an office environment. They scoffed over how bad could a paper cut be? Or, what’s the worst that could happen if someone fell off their chair? Little did they expect that one of their office workers, when on a healthy outdoor walk during her scheduled break time, tripped over some roped off tape that had been blown by the wind. She actually walked into it – not paying attention to her surroundings – got caught up in it as it wrapped about her feet. She fell, twisted her knee, required surgical repair, etc., etc. Try to explain that office worker lost-time injury! (The good: healthy walk; The bad: not paying attention; The ugly: lost time injury). We see organizations as complex adapting networks of people who are the vital keys to its success. When the people in the various parts of the network are sharing information and helping each other, all aspects of EHS Performance rapidly improves, resistance to change disappears and the energy bubbles up spilling over into all other parts of the work lifting the organization to new, higher levels of performance.

We see organizations as complex adapting networks of people who are the vital keys to its success. When the people in the various parts of the network are sharing information and helping each other, all aspects of EHS Performance rapidly improves, resistance to change disappears and the energy bubbles up spilling over into all other parts of the work lifting the organization to new, higher levels of performance. In many places, the hunting season is underway or just beginning. This is always a time of change and hazard. Some years when I was a plant manager, we would have one or two serious hunting-related, off-job injuries – like falling from a tree stand or tripping over something and breaking a leg. There is a lot of change as people go into the woods and fields looking for game. Many have not done this for a while. Others may not be fully prepared for a sharp change in the weather where a heavy rain could come in or the temperatures drop below freezing and hypothermia becomes a worry. It is often dark and visibility is poor. I have read of hunters getting killed with their own weapon when they have tripped and accidentally shot themselves. Don’t load your gun until you are ready to use it.

In many places, the hunting season is underway or just beginning. This is always a time of change and hazard. Some years when I was a plant manager, we would have one or two serious hunting-related, off-job injuries – like falling from a tree stand or tripping over something and breaking a leg. There is a lot of change as people go into the woods and fields looking for game. Many have not done this for a while. Others may not be fully prepared for a sharp change in the weather where a heavy rain could come in or the temperatures drop below freezing and hypothermia becomes a worry. It is often dark and visibility is poor. I have read of hunters getting killed with their own weapon when they have tripped and accidentally shot themselves. Don’t load your gun until you are ready to use it. I have been talking about checklists in my previous newsletters and they can be useful as people go out hunting.

I have been talking about checklists in my previous newsletters and they can be useful as people go out hunting. I recently read of a fatal accident where a man was killed while working on a lathe. It was properly shielded and okay for the normal conditions, but the unexpected happened. The part he was working on exploded apart under the high rotating speed when he engaged the cutter. The parts from the exploding piece went right through the shield and gave him terrible, fatal wounds.

I recently read of a fatal accident where a man was killed while working on a lathe. It was properly shielded and okay for the normal conditions, but the unexpected happened. The part he was working on exploded apart under the high rotating speed when he engaged the cutter. The parts from the exploding piece went right through the shield and gave him terrible, fatal wounds. Another thing that can happen around hunting season and the holidays is the need to hire temporary people to backfill for those who are out. These people need extra care and attention, but things are often so busy that it is hard to give it to them. These people just don’t know the hazards.

Another thing that can happen around hunting season and the holidays is the need to hire temporary people to backfill for those who are out. These people need extra care and attention, but things are often so busy that it is hard to give it to them. These people just don’t know the hazards. In many of my newsletters, I have talked about the importance of sharing information abundantly, building relationships of trust and interdependence, and helping people to see the importance of their own work in building the success of the whole organization.

In many of my newsletters, I have talked about the importance of sharing information abundantly, building relationships of trust and interdependence, and helping people to see the importance of their own work in building the success of the whole organization. “

“ In my reading, studying and talking with many people, I have found that over half of the fatal accidents are often unanticipated and missed using our traditional approaches to accident prevention. The Heinrich Accident Triangle is very useful as we look at unsafe acts at the base of the triangle. Lots of slips, trips and falls are avoided as we do this.

In my reading, studying and talking with many people, I have found that over half of the fatal accidents are often unanticipated and missed using our traditional approaches to accident prevention. The Heinrich Accident Triangle is very useful as we look at unsafe acts at the base of the triangle. Lots of slips, trips and falls are avoided as we do this.