The best approach to sustainable safety excellence is through Partner-Centered Safety.

This is a proven, robust way for dedicated people to work together to get the excellent safety results they want to achieve. All dimensions of occupational safety and health as well as process safety management are positively impacted when people work this way.

There are three main aspects to Partner-Centered Safety.

There are three main aspects to Partner-Centered Safety.

- Developing mutual respect for and valuing each other as real people is critical. My safety mantra was “I don’t have a right to make my living in a place where it is okay for you to get hurt. Now let’s figure out how to work safely and make a profitable business.” With this message, I was trying to convey my deep respect and value for them as individuals. The people really appreciated this way of being together.

- Talking, listening and thinking together, looking for the best solutions and possibilities opened up new ways to do our work, building credibility, trust and interdependence. All of us brought our various experiences, skills and insights into the discussions as equals with a passion for excellence in safety and production. The decisions were made with the best thinking and technology we had rather than by arbitrary, do it my way, orders.

- Our culture shifted so that there was order, some stability and some control along with an openness to freely talking and thinking together to find the best solutions. The ambiguity of order and freedom worked very well as long as we were in constant conversation. For example, we learned to live in the need to have excellent safety and production at the same time.

As we worked this way good ideas bubbled up, new thinking developed, safety improved to Total Injury Rates at 0.3 or better and people discovered that they could sustain this for years (over 17 years in one case). At the same time earnings, productivity and environmental performance improved significantly.

Safety excellence is achieved and sustained one day at a time, day after day.

Safety excellence is achieved and sustained one day at a time, day after day. Yes, the elephant that got in the way of having the conversations that matter? You did? Oh, you have one of those too?

Yes, the elephant that got in the way of having the conversations that matter? You did? Oh, you have one of those too? Another paper from an award-winning company showed their outstanding progress in lowering their total recordable injury rate from around 10 to 0.5 through a steady progress of improvements over 10 years. Their work was out of the Newtonian/Cartesian perspective, quite similar to what Mathis and Galloway teach.

Another paper from an award-winning company showed their outstanding progress in lowering their total recordable injury rate from around 10 to 0.5 through a steady progress of improvements over 10 years. Their work was out of the Newtonian/Cartesian perspective, quite similar to what Mathis and Galloway teach. There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry?

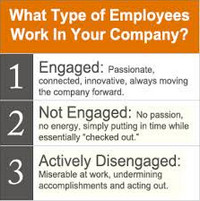

There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry? But, the machine view of organizations is the dominant paradigm right now. We direct the people to work in tight procedures. We manipulate them to do things right. We punish them when there is an injury or incidents. We look for root-cause. We think that if we can take things apart and understand the parts that we can understand the whole. Almost all the effort is engaged in doing things TO the people as if they were just interchangeable parts of a machine. Most people push back against authority in this paradigm. This is a win/lose environment.

But, the machine view of organizations is the dominant paradigm right now. We direct the people to work in tight procedures. We manipulate them to do things right. We punish them when there is an injury or incidents. We look for root-cause. We think that if we can take things apart and understand the parts that we can understand the whole. Almost all the effort is engaged in doing things TO the people as if they were just interchangeable parts of a machine. Most people push back against authority in this paradigm. This is a win/lose environment. People are often reluctant to speak up in these negative environments. Ideas for improvement never surface. New employees are negatively influenced and led astray. Supervisors have a very rough time getting the people to do their work properly. Grievance rates are high and much time is wasted needlessly because these are not addressed at an early stage.

People are often reluctant to speak up in these negative environments. Ideas for improvement never surface. New employees are negatively influenced and led astray. Supervisors have a very rough time getting the people to do their work properly. Grievance rates are high and much time is wasted needlessly because these are not addressed at an early stage. For most managers putting production first can be quite subtle with messages like:

For most managers putting production first can be quite subtle with messages like: Partner-Centered Safety is a robust, proven way to bring people together to achieve sustainable levels of safety excellence being based on deeply held beliefs and values.

Partner-Centered Safety is a robust, proven way to bring people together to achieve sustainable levels of safety excellence being based on deeply held beliefs and values.