The background story:

A recent article in the October 13, 2016 Daily Mail reported a £1.6 Million fine (equivalent of $2 Million) against Disney after actor, Harrison Ford, was crushed by the Millennium Falcon’s hydraulic door on the set of the latest Star Wars Episode VII, “The Force Awakens”, movie which was being filmed in June, 2014.

A recent article in the October 13, 2016 Daily Mail reported a £1.6 Million fine (equivalent of $2 Million) against Disney after actor, Harrison Ford, was crushed by the Millennium Falcon’s hydraulic door on the set of the latest Star Wars Episode VII, “The Force Awakens”, movie which was being filmed in June, 2014.

Ford had gone through the door, hit a button, walked out the door, and unexpectedly turned to walk back through the door when it came down on him. He assumed that the set was not live since it was a rehearsal. In this scene, Ford was helping his injured Wookiee friend through the door into the spacecraft. The door, which was operated by a person who was remotely located and could not see Ford, quickly closed it as he unexpectedly turned back into the spacecraft. Ford screamed and an emergency stop button was pressed, stopping the door just eight inches from being completely shut. They described it like a blunt-edged guillotine with a force comparable to being hit by a small car. Ford was pinned to the ground, suffering a broken tibia and fibula, a dislocated ankle and cut hand. The door had to be opened by the operator.

Disney’s subsidiary, Foodles Production (UK) Ltd., admitted to two counts of safety violations. In the main violation, while the company had done a risk assessment recognizing the risk of death, they had failed to talk to Ford so he was unaware of the precautions he needed to take. In earlier films, the door was operated slowly by a rope and pulley by a stagehand. The mechanized operation moved the door very quickly, surprising the 71-year-old Ford. After Ford’s recovery of about eight weeks, the film was completed.

The Meaning of the Story: Looking at the Blunt End and the Sharp End of Safety

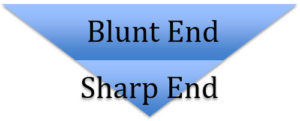

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

Relating this Story to Safety Theory and Practice

In Erik Hollnagel’s book, “Safety-I and Safety-II” (2014. Ashgate Publishing Ltd., Surrey, UK), he discusses ideas like the significance of the gap between “the work-as-imagined” done by managers and engineers planning and designing the work and the “work-as-done” by the people actually doing the work. This is illustrated nicely by the Ford Star Wars incident where the people doing the “work-as-imagined” failed to understand the actual conditions and mindset of Ford doing the “work-as-done.”

In Erik Hollnagel’s book, “Safety-I and Safety-II” (2014. Ashgate Publishing Ltd., Surrey, UK), he discusses ideas like the significance of the gap between “the work-as-imagined” done by managers and engineers planning and designing the work and the “work-as-done” by the people actually doing the work. This is illustrated nicely by the Ford Star Wars incident where the people doing the “work-as-imagined” failed to understand the actual conditions and mindset of Ford doing the “work-as-done.”

Hollnagel describes the way in which we have traditionally done our safety work as reactive and where so much of it relates to “work-as-imagined” as Safety-I. The gap between where the “work-as-imagined” and “work-as-done” is where there are very difficult communication challenges. We tend to react to what has gone wrong. Bridging this gap moves our safety work into Safety-II where we move into the world of more performance variability, more adaptability and resilience. This is a world where everyone needs a better understanding of how and why things work, particularly our organizations. It is a world where we need to have a sense of both the whole and the parts. It is a world where we focus more on understanding what is going right than just on what went wrong. It is a world where we are more proactive in our safety work.

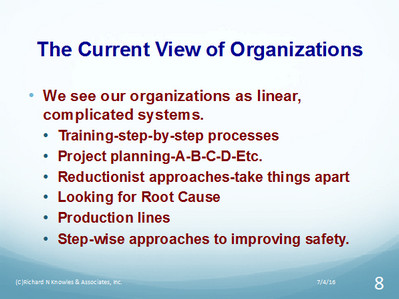

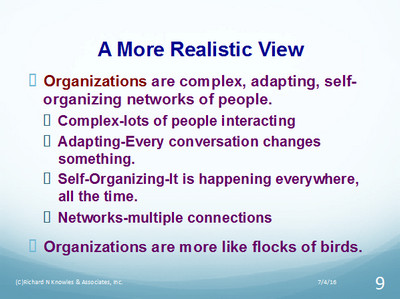

The Bottom Line: Re-engaging the Force…People and Business Together

At Richard N. Knowles & Associates, we help organizations move into a world similar to Hollnagel’s Safety-II world. Our work environments and tasks are complex. Our organizations are complex, adapting, self-organizing networks of people. Building on these ideas, we help organizations to learn how to open up the communications, to engage everyone, to help and support each other, to listen and learn from each other, and connect real caring with the work that needs to be done. We help organizations to reconcile the relationship between the needs of the business and the needs of the people, which results in the release of enormous energy and creativity.

Give us a call so we can explore this more fully with you and help you see the sorts of improvements you and your people can make. We are here at 716-622-6467 to meet your needs.

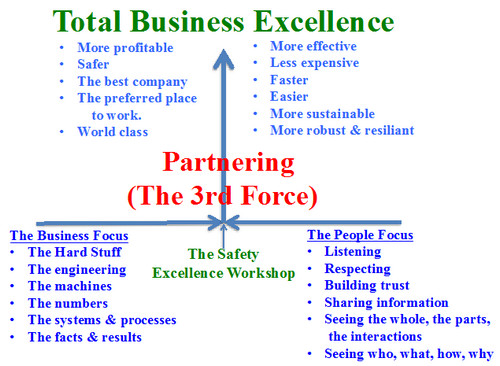

For our workplaces, this is about the way we think about safety, the way we engage around safety, and the way we bring a third unifying force to the whole culture of safety.It’s the missing link in our respective workplaces. Without it, we tend to stay engulfed in a culture of compliance, yet despite trying and trying, we never reach excellence. Without it, we keep repeating the same mistakes – round and round we go.

For our workplaces, this is about the way we think about safety, the way we engage around safety, and the way we bring a third unifying force to the whole culture of safety.It’s the missing link in our respective workplaces. Without it, we tend to stay engulfed in a culture of compliance, yet despite trying and trying, we never reach excellence. Without it, we keep repeating the same mistakes – round and round we go. I spoke about Partner-Centered Safety™ and the importance of this as the quickest way to achieve sustainable safety excellence. As many of you know, I have written and spoken about this many times over the last several years. The information and data I share clearly shows that this approach to leading safety is very powerful, producing improved results quite quickly. Many of you have seen the terrific results the people at the DuPont, Belle Plant achieved. This approach has a very strong scientific basis in complex adaptive systems theory.

I spoke about Partner-Centered Safety™ and the importance of this as the quickest way to achieve sustainable safety excellence. As many of you know, I have written and spoken about this many times over the last several years. The information and data I share clearly shows that this approach to leading safety is very powerful, producing improved results quite quickly. Many of you have seen the terrific results the people at the DuPont, Belle Plant achieved. This approach has a very strong scientific basis in complex adaptive systems theory.

When the Safety Culture is right…what do you see? What does Excellence look like?

When the Safety Culture is right…what do you see? What does Excellence look like?

In many places, the hunting season is underway or just beginning. This is always a time of change and hazard. Some years when I was a plant manager, we would have one or two serious hunting-related, off-job injuries – like falling from a tree stand or tripping over something and breaking a leg. There is a lot of change as people go into the woods and fields looking for game. Many have not done this for a while. Others may not be fully prepared for a sharp change in the weather where a heavy rain could come in or the temperatures drop below freezing and hypothermia becomes a worry. It is often dark and visibility is poor. I have read of hunters getting killed with their own weapon when they have tripped and accidentally shot themselves. Don’t load your gun until you are ready to use it.

In many places, the hunting season is underway or just beginning. This is always a time of change and hazard. Some years when I was a plant manager, we would have one or two serious hunting-related, off-job injuries – like falling from a tree stand or tripping over something and breaking a leg. There is a lot of change as people go into the woods and fields looking for game. Many have not done this for a while. Others may not be fully prepared for a sharp change in the weather where a heavy rain could come in or the temperatures drop below freezing and hypothermia becomes a worry. It is often dark and visibility is poor. I have read of hunters getting killed with their own weapon when they have tripped and accidentally shot themselves. Don’t load your gun until you are ready to use it. I have been talking about checklists in my previous newsletters and they can be useful as people go out hunting.

I have been talking about checklists in my previous newsletters and they can be useful as people go out hunting. I recently read of a fatal accident where a man was killed while working on a lathe. It was properly shielded and okay for the normal conditions, but the unexpected happened. The part he was working on exploded apart under the high rotating speed when he engaged the cutter. The parts from the exploding piece went right through the shield and gave him terrible, fatal wounds.

I recently read of a fatal accident where a man was killed while working on a lathe. It was properly shielded and okay for the normal conditions, but the unexpected happened. The part he was working on exploded apart under the high rotating speed when he engaged the cutter. The parts from the exploding piece went right through the shield and gave him terrible, fatal wounds. Another thing that can happen around hunting season and the holidays is the need to hire temporary people to backfill for those who are out. These people need extra care and attention, but things are often so busy that it is hard to give it to them. These people just don’t know the hazards.

Another thing that can happen around hunting season and the holidays is the need to hire temporary people to backfill for those who are out. These people need extra care and attention, but things are often so busy that it is hard to give it to them. These people just don’t know the hazards. At our exhibit booth, Claire and I shared our Partner-Centered Leadership approach. We handed out brochures and other literature that can help organization’s achieve safety excellence and move towards their OSHA Star designation. We were there to share important information, including the need to be able to lift up and address one’s safety elephants that are preventing organizations from being the best they can be.

At our exhibit booth, Claire and I shared our Partner-Centered Leadership approach. We handed out brochures and other literature that can help organization’s achieve safety excellence and move towards their OSHA Star designation. We were there to share important information, including the need to be able to lift up and address one’s safety elephants that are preventing organizations from being the best they can be. The keys for addressing both of these concerns in building sustainability into their programs and in achieving the OSHA Star status is for the people at all levels and parts of the organization to talk together to get clear and aligned on just what they really want to do. How sincere and authentic is the desire to have safety excellence for the long-term? (This means Communication with a Capital C—requiring Co-creation, Clarity and Coherence.) In addition, together they must take the time to co-create a set of ground rules about how they agree to work together in order to achieve their safety goals and then hold each other accountable to live up to them. (That’s Partnership and Commitment!) The process to achieve this is available to you and your organizations now.

The keys for addressing both of these concerns in building sustainability into their programs and in achieving the OSHA Star status is for the people at all levels and parts of the organization to talk together to get clear and aligned on just what they really want to do. How sincere and authentic is the desire to have safety excellence for the long-term? (This means Communication with a Capital C—requiring Co-creation, Clarity and Coherence.) In addition, together they must take the time to co-create a set of ground rules about how they agree to work together in order to achieve their safety goals and then hold each other accountable to live up to them. (That’s Partnership and Commitment!) The process to achieve this is available to you and your organizations now. This is all about having everyone go home in one piece and having a profitable business. Excellence in both the safety performance and business results are attainable.

This is all about having everyone go home in one piece and having a profitable business. Excellence in both the safety performance and business results are attainable. “

“ Talking together is one of the most important things we can do to help to improve the safety in our workplaces. Letting people know that you care about them and respect them. But too many times I have seen supervisors and managers talking down to their employees ordering them to do this or that.

Talking together is one of the most important things we can do to help to improve the safety in our workplaces. Letting people know that you care about them and respect them. But too many times I have seen supervisors and managers talking down to their employees ordering them to do this or that. At a recent safety conference I learned about a way to quickly assess whether a manufacturing site was cutting corners and trying to get by on less than the best. The person speaking, Ewan Alexander of BHP Billiton, said that he looked for improvised tools being used.

At a recent safety conference I learned about a way to quickly assess whether a manufacturing site was cutting corners and trying to get by on less than the best. The person speaking, Ewan Alexander of BHP Billiton, said that he looked for improvised tools being used.  Safety excellence is achieved and sustained one day at a time, day after day.

Safety excellence is achieved and sustained one day at a time, day after day.