This is another dimension of our workplace safety challenges. Our focus here is to prevent deliberate harm to one another. Terrible tragedies are created when someone brings a gun into one’s workplace and starts shooting. But our concern here goes more broadly than these incidents. Frustrated, angry people can do mean things to each other by sexually harassing, bullying, or repeatedly picking on those who are seen as weak or at a disadvantage. OSHA reports that about 2,000,000 cases like this are reported each year. How many more go unreported?

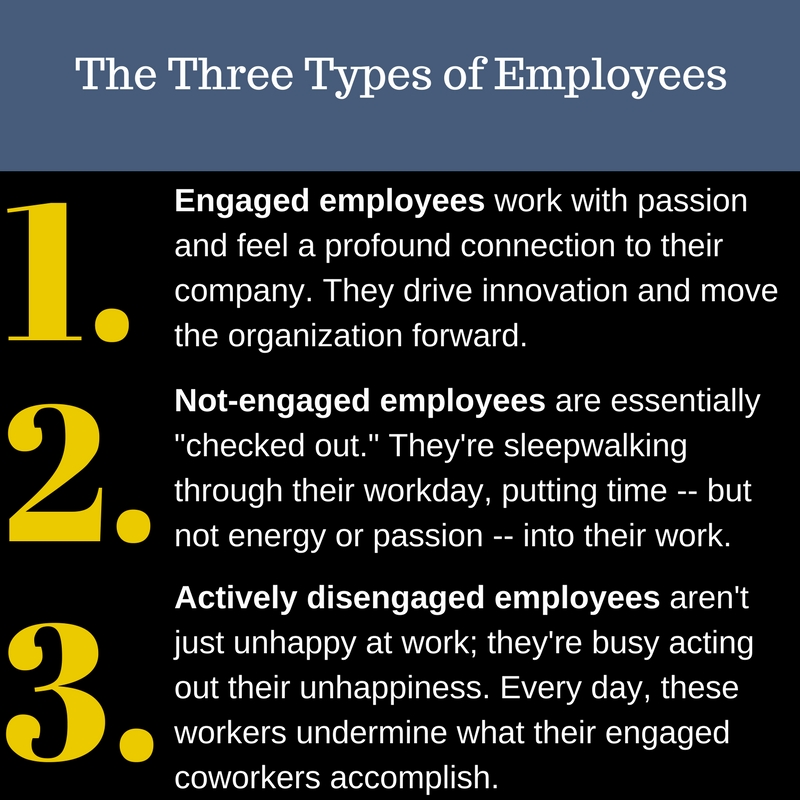

I have read surveys that indicate that up to 80% of the people in our organizations are frustrated and unhappy. In these sorts of hostile environments, bad feelings can fester and grow to the point where they blow up and people get hurt in one way or another. It doesn’t have to be that way!

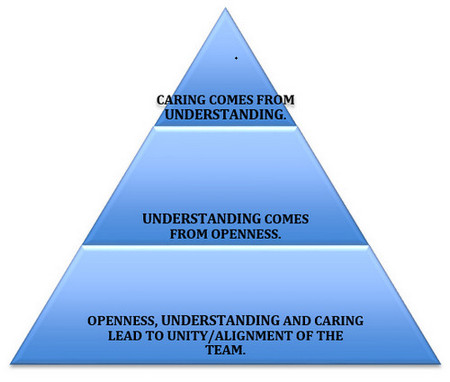

A step towards preventing workplace violence is to use the Partner-Centered Leadership (Engagement) Process. As we learn to work together, talk together, listen to each other, and build trust and interdependence, we create an environment that is more supportive, caring and effective. (It doesn’t take long to uncover the obvious: rudeness, disrespect and unprofessionalism lead to incivility and discord, which in turn, leads to bullying and harassment, which in turn, can accelerate to Workplace Violence – physical or mental.)

The steps I suggested in the first part of this newsletter are good ones to use to help to make our workplaces more kind, supportive and healthy. We can all do this if we want to do it! Increasing our levels of positive engagement with all our people is the key to healthy workplaces. The Partner-Centered Leadership Process is the way.

As the snow begins to melt and the spring winds arrive, it is time for cleaning up the place. Mud season is upon us as the snow melts. All sorts of curious things emerge from the melting piles of snow; stuff that was covered up and lost. (Just imagine: Years ago the settlers kept their animals sheltered next to their houses or barns attached to their houses so that they could care for them when the winter cold set in. They really had to do the spring-cleaning!)

As the snow begins to melt and the spring winds arrive, it is time for cleaning up the place. Mud season is upon us as the snow melts. All sorts of curious things emerge from the melting piles of snow; stuff that was covered up and lost. (Just imagine: Years ago the settlers kept their animals sheltered next to their houses or barns attached to their houses so that they could care for them when the winter cold set in. They really had to do the spring-cleaning!)

Each time the construction cycle picks up, more people get killed, mostly from falls. Some falls are the result of poor footing. Some falls result from poor housekeeping and clutter. Some falls result from inadequate barricading of edges or open holes in the floors. Some falls result from poor pre-shift preparations and the work is started before things are ready. Some falls result from people rushing to get the work done quickly. Some falls result from some people being careless.

Each time the construction cycle picks up, more people get killed, mostly from falls. Some falls are the result of poor footing. Some falls result from poor housekeeping and clutter. Some falls result from inadequate barricading of edges or open holes in the floors. Some falls result from poor pre-shift preparations and the work is started before things are ready. Some falls result from people rushing to get the work done quickly. Some falls result from some people being careless. With all the uncertainties and variable working conditions, all of you need to be looking out for each other – I mean really watching and helping each other. Being ready and willing to stop unsafe work is important. It is critical that information flows freely so that everyone knows what is going on and are able to work closely together.

With all the uncertainties and variable working conditions, all of you need to be looking out for each other – I mean really watching and helping each other. Being ready and willing to stop unsafe work is important. It is critical that information flows freely so that everyone knows what is going on and are able to work closely together. We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses.

We know that it can, and we prove it over and over again, as we work with leaders, their teams, and their businesses. Our new year is full of opportunities, dark clouds and unknowns. The world is full of strife of all sorts. Our political situation here in the U.S. is full of hope, tension, noise, and unknowns. So many people are screaming about their opinions that it is almost impossible to hear. I get so tired of it that I often just quit trying to listen. That is probably a mistake for me to do that; we are all connected and I can’t just go away and hide. None of us can do that.

Our new year is full of opportunities, dark clouds and unknowns. The world is full of strife of all sorts. Our political situation here in the U.S. is full of hope, tension, noise, and unknowns. So many people are screaming about their opinions that it is almost impossible to hear. I get so tired of it that I often just quit trying to listen. That is probably a mistake for me to do that; we are all connected and I can’t just go away and hide. None of us can do that. As we bring this sort of thinking and being together into our workplaces, we can seek ways to improve our safety performance and business results. I have found over and over that we can vastly improve our safety and business performance when we share information together, listen for understanding, develop trust among us and see how well are all contributing, solutions emerge. When we help to change the behavior of bullies of get them out of the work place, we get even better.

As we bring this sort of thinking and being together into our workplaces, we can seek ways to improve our safety performance and business results. I have found over and over that we can vastly improve our safety and business performance when we share information together, listen for understanding, develop trust among us and see how well are all contributing, solutions emerge. When we help to change the behavior of bullies of get them out of the work place, we get even better. A recent article in the October 13, 2016

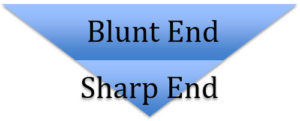

A recent article in the October 13, 2016  This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen.

This story illustrates so many of the changing conditions and people involved in our work places. Most of our companies do a good job in risk assessments and developing safe working procedures. However, this planning often takes place away from the actual location where the work will be done. This is sometimes called the “blunt end” of the safety process where the people doing the planning do not understand what happens in the work at “sharp-end” where conditions and demands may be quite different, and where most of the injuries happen. In Erik Hollnagel’s book, “Safety-I and Safety-II” (2014. Ashgate Publishing Ltd., Surrey, UK), he discusses ideas like the significance of the gap between “the work-as-imagined” done by managers and engineers planning and designing the work and the “work-as-done” by the people actually doing the work. This is illustrated nicely by the Ford Star Wars incident where the people doing the “work-as-imagined” failed to understand the actual conditions and mindset of Ford doing the “work-as-done.”

In Erik Hollnagel’s book, “Safety-I and Safety-II” (2014. Ashgate Publishing Ltd., Surrey, UK), he discusses ideas like the significance of the gap between “the work-as-imagined” done by managers and engineers planning and designing the work and the “work-as-done” by the people actually doing the work. This is illustrated nicely by the Ford Star Wars incident where the people doing the “work-as-imagined” failed to understand the actual conditions and mindset of Ford doing the “work-as-done.” Consider the Golden Gate Suspension Bridge (San Francisco) built between 1933 and 1937, an architectural marvel, thought to be impossible because in order to bridge that 6,700 ft. strait, in the middle of the bay channel, against strong tides, fierce winds, and thick fog, meant overcoming almost impossible odds. But it was built, with a grand opening in May of 1937, deemed, at the time of its completion, to be the tallest suspension bridge in the world as well as the longest. A man named Joseph Strauss engineered many new ideas, including developing safety devices such as movable netting, which saved 19 lives; though in all, there were 11 men lost during this construction. Thousands of men – workers of varying ages and from varied ethnic groups – came together to complete this project. (They had to listen and learn to be successful together.)

Consider the Golden Gate Suspension Bridge (San Francisco) built between 1933 and 1937, an architectural marvel, thought to be impossible because in order to bridge that 6,700 ft. strait, in the middle of the bay channel, against strong tides, fierce winds, and thick fog, meant overcoming almost impossible odds. But it was built, with a grand opening in May of 1937, deemed, at the time of its completion, to be the tallest suspension bridge in the world as well as the longest. A man named Joseph Strauss engineered many new ideas, including developing safety devices such as movable netting, which saved 19 lives; though in all, there were 11 men lost during this construction. Thousands of men – workers of varying ages and from varied ethnic groups – came together to complete this project. (They had to listen and learn to be successful together.) Consider the feat of building the monumental Hoover Dam (1931-1936) – a miracle of technology and engineering. No dam project of this scale had ever been attempted before. There were 21,000 people working at that site with approximately 100 industrial deaths. The walls for this structure – that would uphold the weight of the dam – required workers called “high-scalers” who excavated the cliffs, dangling on ropes from the rim of the canyon. Can you even fathom this?

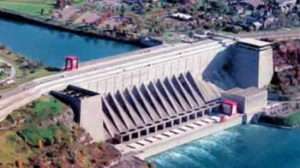

Consider the feat of building the monumental Hoover Dam (1931-1936) – a miracle of technology and engineering. No dam project of this scale had ever been attempted before. There were 21,000 people working at that site with approximately 100 industrial deaths. The walls for this structure – that would uphold the weight of the dam – required workers called “high-scalers” who excavated the cliffs, dangling on ropes from the rim of the canyon. Can you even fathom this? Consider the great Niagara Power Project (1957-1961). During construction, over 12 million cubic yards of rock were excavated. A total of 20 workers died. When it opened in 1961, it was the Western world’s largest hydropower facility. Many people, including from the “greatest generation” and the “traditionalist generation,” worked together on this project. It was a 24/7, multi-year project.

Consider the great Niagara Power Project (1957-1961). During construction, over 12 million cubic yards of rock were excavated. A total of 20 workers died. When it opened in 1961, it was the Western world’s largest hydropower facility. Many people, including from the “greatest generation” and the “traditionalist generation,” worked together on this project. It was a 24/7, multi-year project. In my June 29th presentation at the American Society of Safety Engineers 2016 Professional Development Conference, I discussed the fact that one of the best ways for the safety professional attending the talk to help to improve the safety performance in their workplaces was to show the people that they cared about them and to enable them to make decisions about their specific work. I want to elaborate on these ideas in this newsletter. This is not just for the safety professional. This is for every team leader, supervisor, and workgroup leader. Going into your workplaces and opening up the conversations is a journey; each time you do this it gets easier and more effective. (Caring, Understanding and Openness!)

In my June 29th presentation at the American Society of Safety Engineers 2016 Professional Development Conference, I discussed the fact that one of the best ways for the safety professional attending the talk to help to improve the safety performance in their workplaces was to show the people that they cared about them and to enable them to make decisions about their specific work. I want to elaborate on these ideas in this newsletter. This is not just for the safety professional. This is for every team leader, supervisor, and workgroup leader. Going into your workplaces and opening up the conversations is a journey; each time you do this it gets easier and more effective. (Caring, Understanding and Openness!) Eighty (80) pages and counting…that’s how far I got while perusing the numerous pages for the 2015 fatalities logged on OSHA reports – there were still many names and circumstances yet to read.

Eighty (80) pages and counting…that’s how far I got while perusing the numerous pages for the 2015 fatalities logged on OSHA reports – there were still many names and circumstances yet to read.

Hardly any of us can do our best work all by ourselves.

Hardly any of us can do our best work all by ourselves.