In Orlando, Florida, there is a $2.3 billion, 21-mile, I-4 highway improvement project that has been underway since 2015. It is such a traffic headache that we try to avoid it as much as we can when we are driving across Florida.

There have been five fatalities since the project began. All five of the fatalities have been “struck-by” incidents. The most recent occurred about October 1st, when a beam slipped off a piece of equipment and struck a worker on the head. One person was hit by a dump truck. Another died when he was hit by a piece of steel equipment. The fourth person died when a rebar cage fell on him, and the fifth person was killed when he was hit in the head by a pipe.

There have been five fatalities since the project began. All five of the fatalities have been “struck-by” incidents. The most recent occurred about October 1st, when a beam slipped off a piece of equipment and struck a worker on the head. One person was hit by a dump truck. Another died when he was hit by a piece of steel equipment. The fourth person died when a rebar cage fell on him, and the fifth person was killed when he was hit in the head by a pipe.

All construction was suspended to review the safety plans and to get everyone refocused on working safely. OSHA and safety experts have been involved in the analyses, “Until the root causes are determined, girder erection and installation are suspended.”

Suspending the work to get everyone focused, bringing in safety experts, and seeking root causes are a start, but they will not, in themselves, stop the fatal accidents. There is so much more going on that there are no root causes. The pressures to get the projects going again are intense.

There’s A Deeper Pattern…

Every fatality was a “struck-by” incident, which indicates that things are moving when the incidents happened. On projects like this one, there is huge pressure to keep on schedule and get the work done. The pressure to move too fast is great. Yet, as these incidents show, going faster results in things going more slowly, and people getting killed. Hurrying is a big problem!

Each person needs to be looking out for the others, talking together about how to do the job without anyone getting hurt, sharing ideas about how to do the work more effectively and safely. Supervisors and managers need to be talking with the people about getting the jobs done effectively and safely. Everyone needs to be kept informed on the status of the work and the details for each day’s work.

Toolbox meetings are a critical element in this. Everyone needs to be able to shut down a job if they see that there are safety issues that need to be addressed. Coming together to form safety teams to help build the focus on specific tasks would be useful. Building an environment where everyone is treated with respect and is open to having people speak up, be able to ask questions and look for better ways is important.

But working this way will be a challenge for them. They have many separate contractors, many people of different skill levels, and a worksite spread over 21 miles.

When I have talked with people in other situations about working this way, I often get funny looks. They tell me that they do not have time to work this way. They have to get the job done!

My belief is that they really do have to take the time to work this way because, in my experience, working this way is the fastest, safest and least costly way to get the work done. Just think about all the time that is lost and distractions that occur in investigations, dealing with OSHA, job shutdowns, fighting the unions, dealing with the lawyers, the media and the families that have suffered a loss of a loved one.

Working fast, ignoring the people, taking short-cuts and cutting corners all lead to higher costs, project delays and more people getting hurt. Call me 716-622-6467 and let’s talk deeper-pattern safety!

Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are fractured and coming apart. Change is coming faster and faster. So many people seem to be trying to cope by pulling into their shells and trying to push the turmoil all away. The trust levels among all the various groups is very low. So many loud voices are pushing their version of the “truth” that it is almost impossible to tell who is being honest and should be listened to. How do we find the truth?

Our businesses, our schools and hospitals, our governments, and not-for-profits, at all levels, are fractured and coming apart. Change is coming faster and faster. So many people seem to be trying to cope by pulling into their shells and trying to push the turmoil all away. The trust levels among all the various groups is very low. So many loud voices are pushing their version of the “truth” that it is almost impossible to tell who is being honest and should be listened to. How do we find the truth? In thinking about your own place of work, what do you suppose it would be like if people did some of the things mentioned earlier in this newsletter? Do you think that you could begin talking with others about building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like improving the safety of your job? What would it be like if the managers and supervisors talked frequently about with everyone about how the business was doing the challenges from the competition? What would it be like if you knew that someone was looking out for your back? What would it be like if you felt you were in an environment of trust? What would it be like if people really asked important questions and talked about them? What would it be like if people in upper management asked you for your honest opinion and really listened? That’s called breaking the iceberg and engaging in authentic conversations!

In thinking about your own place of work, what do you suppose it would be like if people did some of the things mentioned earlier in this newsletter? Do you think that you could begin talking with others about building a more respectful environment? What do you think it would be like if you could openly talk together about the important issues like improving the safety of your job? What would it be like if the managers and supervisors talked frequently about with everyone about how the business was doing the challenges from the competition? What would it be like if you knew that someone was looking out for your back? What would it be like if you felt you were in an environment of trust? What would it be like if people really asked important questions and talked about them? What would it be like if people in upper management asked you for your honest opinion and really listened? That’s called breaking the iceberg and engaging in authentic conversations! For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM.

For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM. Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production.

Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production. One director of a large organization of various businesses was completely unaware of the problem among their members. This is amazing since the statistics show that problems like bullying and sexual harassment are occurring in way over 50% of the organizations in our country. Apparently none of the businesses in this organization feel it is important to think about and discuss.

One director of a large organization of various businesses was completely unaware of the problem among their members. This is amazing since the statistics show that problems like bullying and sexual harassment are occurring in way over 50% of the organizations in our country. Apparently none of the businesses in this organization feel it is important to think about and discuss. There seems to be an interesting disconnect here. OSHA does focus on falls, but what about roadway deaths and homicides? These are serious workplace problems as well. What about the whole problem of workplace violence that begins with the lack of respect (bullying, harassment), and that can lead to serious business problems like poor productivity, high absenteeism, fighting, injuries, murder, and suicide?

There seems to be an interesting disconnect here. OSHA does focus on falls, but what about roadway deaths and homicides? These are serious workplace problems as well. What about the whole problem of workplace violence that begins with the lack of respect (bullying, harassment), and that can lead to serious business problems like poor productivity, high absenteeism, fighting, injuries, murder, and suicide? The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing. A review of the Bureau of Labor Statics summary of fatal occupational injuries for 2011-2017 shows a 1% drop in fatalities from 2016 to 2017 to a total of 5,147 people having lost their lives at work. This is about 9% higher than the 4,693 people killed in 2011. The top three 2017 fatalities categories are roadway accidents totaling 1,299 (up 15% since 2011); slips, trips and falls totaling 887 (up 23% since 2011); and murders and suicides totaling 733 (up by only 2% since 2011).

A review of the Bureau of Labor Statics summary of fatal occupational injuries for 2011-2017 shows a 1% drop in fatalities from 2016 to 2017 to a total of 5,147 people having lost their lives at work. This is about 9% higher than the 4,693 people killed in 2011. The top three 2017 fatalities categories are roadway accidents totaling 1,299 (up 15% since 2011); slips, trips and falls totaling 887 (up 23% since 2011); and murders and suicides totaling 733 (up by only 2% since 2011). We need courageous leaders who focus on the people, change and the future. Leaders value sharing information, building trust and interdependence, and helping people to see how their job is important for the success of the whole venture.

We need courageous leaders who focus on the people, change and the future. Leaders value sharing information, building trust and interdependence, and helping people to see how their job is important for the success of the whole venture. Go into your organizations listening to and talking with the people. Share your vision. Build trust and interdependence. Create safe spaces for people to talk with each other, to share and create the future. Everything will change. That is what I experienced at the Belle Plant.

Go into your organizations listening to and talking with the people. Share your vision. Build trust and interdependence. Create safe spaces for people to talk with each other, to share and create the future. Everything will change. That is what I experienced at the Belle Plant. It is a new year. Businesses have compiled their 2018 safety statistics. They are looking at economics and at people. Who was hurt during this past year? What have we put in place so that those injuries won’t happen again? What are we talking about together for betterment? How did our systems contribute to our successes or to the injurie/s? What was the presence and the strength of Leadership support like around those people who were injured? Where are we most vulnerable safety-wise? How can we lead more effectively? How can we have an even safer workplace in this new year, 2019? How can we help employees to become more aware, more safety vigilant? And thus more able to return to their families at the end of the shift whole – with arms, legs, toes, fingers, eyes, ears – all intact. (Leaders, are you asking these questions?)

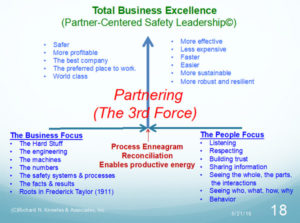

It is a new year. Businesses have compiled their 2018 safety statistics. They are looking at economics and at people. Who was hurt during this past year? What have we put in place so that those injuries won’t happen again? What are we talking about together for betterment? How did our systems contribute to our successes or to the injurie/s? What was the presence and the strength of Leadership support like around those people who were injured? Where are we most vulnerable safety-wise? How can we lead more effectively? How can we have an even safer workplace in this new year, 2019? How can we help employees to become more aware, more safety vigilant? And thus more able to return to their families at the end of the shift whole – with arms, legs, toes, fingers, eyes, ears – all intact. (Leaders, are you asking these questions?) In our November Safety Newsletter, I wrote about Partner-Centered Leadership. This is the most effective way to improve safety performance. This way of leading also results in improvements in most other aspects of the business as trust and interdependence are built and the environment is safe for the open flow of information. A key aspect of this is working with the people.

In our November Safety Newsletter, I wrote about Partner-Centered Leadership. This is the most effective way to improve safety performance. This way of leading also results in improvements in most other aspects of the business as trust and interdependence are built and the environment is safe for the open flow of information. A key aspect of this is working with the people.

The patterns at work are also changing as the business activities and demands are changing. There are not enough good, trained people to fill all the openings so the pressure on everyone is going up. Everything at work happens through people so it is critical that we keep everyone engaged in helping to achieve our successes. We need to open up the trust and build interdependence among everyone to keep the information flowing freely. It is clear how important genuine engagement is within our workplaces.

The patterns at work are also changing as the business activities and demands are changing. There are not enough good, trained people to fill all the openings so the pressure on everyone is going up. Everything at work happens through people so it is critical that we keep everyone engaged in helping to achieve our successes. We need to open up the trust and build interdependence among everyone to keep the information flowing freely. It is clear how important genuine engagement is within our workplaces. They are totally unconscious that they are an important part of networks at work and at home. Many are the bread winners and if they get hurt or killed, they will cause their loved ones terrible hurt and trouble. The indifference of so many people in supervisory or management positions to this sort of behavior is terrible.

They are totally unconscious that they are an important part of networks at work and at home. Many are the bread winners and if they get hurt or killed, they will cause their loved ones terrible hurt and trouble. The indifference of so many people in supervisory or management positions to this sort of behavior is terrible.