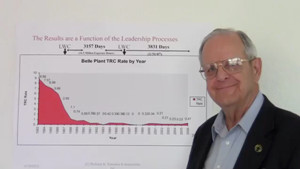

“Safety 2015,” the Annual ASSE Professional Development Conference and Exposition, was held in Dallas, Texas, in early June. It was a terrific conference and gathering of about 4,000 safety professionals. There was a lot of networking, excellent keynote talks, a vast array of all kinds of safety equipment, and lots of papers in concurrent sessions. About 100 people came to hear me talk about achieving sustainable and excellent levels of performance. Total Recordable Injury Rate was <0.4 for 16 years when we approached the organization as a complex adaptive system (CAS).

“Safety 2015,” the Annual ASSE Professional Development Conference and Exposition, was held in Dallas, Texas, in early June. It was a terrific conference and gathering of about 4,000 safety professionals. There was a lot of networking, excellent keynote talks, a vast array of all kinds of safety equipment, and lots of papers in concurrent sessions. About 100 people came to hear me talk about achieving sustainable and excellent levels of performance. Total Recordable Injury Rate was <0.4 for 16 years when we approached the organization as a complex adaptive system (CAS).

There was a lot of interest in this based on the attention of the audience, the quality of the questions and the excellent feedback I received at the end. This was the only paper addressing the complex adaptive systems approach to achieving safety excellence at this conference. Based on my experience, this is a much easier and more effective way to lead safety. The Safety Leadership Process©, the correct tool for use in CAS, requires the leaders to get clear and focused in their safety thinking and message, then go into their organizations listening, talking, abundantly sharing information with the people about how to get better and then helping the people to implement their improvement ideas.

While the conference and exposition presented lots of good papers and displayed a huge array of safety equipment, I got the feeling that a lot of people think that they are disempowered for making safety improvements. Many lament, if only management would listen to the safety professionals, or if we added more focused safety people, or if we could purchase more of the fancy new equipment like that on display, that maybe then our safety would get better. Is this not more of the same way we have been managing safety for years?

I think that more technical papers, more traditional training activities, and new safety equipment will only get the organization to the level of safety compliance – it does not get organizations to the level of safety excellence. I have tried this technical-based approach over the last 50 years without achieving safety excellence. And why? Because people are the key!

But, when I shifted to using the Safety Leadership Process©, described above, the shift in attitude, the willingness to improve performance, and the energy and excitement of the people, enabled the organization to reach and sustain the higher level safety excellence.

Those in leadership positions and at the top of the organization have the responsibility to engage with the people – setting the conditions where excellence can be achieved. This only requires a commitment to get clear on the safety message, go into the work places and engage with the people exploring new and better ways to having every one go home without having been injured at work. With courage, care, concern, and commitment, we can all reach and sustain the level of safety excellence!

At a recent safety conference I learned about a way to quickly assess whether a manufacturing site was cutting corners and trying to get by on less than the best. The person speaking, Ewan Alexander of BHP Billiton, said that he looked for improvised tools being used.

At a recent safety conference I learned about a way to quickly assess whether a manufacturing site was cutting corners and trying to get by on less than the best. The person speaking, Ewan Alexander of BHP Billiton, said that he looked for improvised tools being used.  Safety excellence is achieved and sustained one day at a time, day after day.

Safety excellence is achieved and sustained one day at a time, day after day. There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry?

There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry?

When I began to learn about chaos and complexity science, I saw that this was the way to handle the high level of change. As we shared more and more information, helped people to really understand the nature of the business and their important roles in its success, and as we built more trust and interdependence, people began to step forward to help us take on all the changes that poured into our organization. I did not have to do everything myself, which was a great relief.

When I began to learn about chaos and complexity science, I saw that this was the way to handle the high level of change. As we shared more and more information, helped people to really understand the nature of the business and their important roles in its success, and as we built more trust and interdependence, people began to step forward to help us take on all the changes that poured into our organization. I did not have to do everything myself, which was a great relief. It was fascinating to see the contrast between the usual, linear, mechanical approach to safety and The Complexity Leadership Process (CLP) that I discussed at my display table. A large number of people talked with me at my display table about The Complexity Leadership Process which was new to all of them. Many could not believe how quickly and dramatically the safety performance improved using the CLP. At one level the CLP looks like a simple employee involvement program, yet it is much more and also different at a deeper level than the usual employee involvement processes. One fellow, who recently wrote a book about changing the safety culture to excellence just brushed the CLP aside as something he’d already seen. The approach to safety excellence he’s written about involves 43 linear steps that take 3-5 times as long as the CLP and require a very high level of persistence and determination over many years.

It was fascinating to see the contrast between the usual, linear, mechanical approach to safety and The Complexity Leadership Process (CLP) that I discussed at my display table. A large number of people talked with me at my display table about The Complexity Leadership Process which was new to all of them. Many could not believe how quickly and dramatically the safety performance improved using the CLP. At one level the CLP looks like a simple employee involvement program, yet it is much more and also different at a deeper level than the usual employee involvement processes. One fellow, who recently wrote a book about changing the safety culture to excellence just brushed the CLP aside as something he’d already seen. The approach to safety excellence he’s written about involves 43 linear steps that take 3-5 times as long as the CLP and require a very high level of persistence and determination over many years. I’ll be participating as a sponsor for the Conference Program Brochure. I’ll have an ad in the Brochure as well as a display table. My tag line is “When safety gets right, everything else gets right”. Since I am not an official speaker, I am going to use my display table as an opportunity to talk with people about the

I’ll be participating as a sponsor for the Conference Program Brochure. I’ll have an ad in the Brochure as well as a display table. My tag line is “When safety gets right, everything else gets right”. Since I am not an official speaker, I am going to use my display table as an opportunity to talk with people about the  This Blog is focused on my new book, The Process Enneagram©: Essays on Theory and Practice. I am the editor for this book that was just published by Emergent Publications. It can be purchased directly from their

This Blog is focused on my new book, The Process Enneagram©: Essays on Theory and Practice. I am the editor for this book that was just published by Emergent Publications. It can be purchased directly from their