At our exhibit booth, Claire and I shared our Partner-Centered Leadership approach. We handed out brochures and other literature that can help organization’s achieve safety excellence and move towards their OSHA Star designation. We were there to share important information, including the need to be able to lift up and address one’s safety elephants that are preventing organizations from being the best they can be.

At our exhibit booth, Claire and I shared our Partner-Centered Leadership approach. We handed out brochures and other literature that can help organization’s achieve safety excellence and move towards their OSHA Star designation. We were there to share important information, including the need to be able to lift up and address one’s safety elephants that are preventing organizations from being the best they can be.

We talked with a lot of people and learned of their safety journeys:

- Those who had attained their Star status were looking for ways to sustain their performance, but there was a deep concern that complacency was undermining their safety achievements. Sustaining their work was a goal.

- Those who were working towards their OSHA Star status were often struggling with communications problems between and among the workers, the union, and even the supervisors and managers. Getting everyone on the same page, and committed to the endeavor seems insurmountable (to some).

The Keys to Success and Sustaining Safety Performance

The keys for addressing both of these concerns in building sustainability into their programs and in achieving the OSHA Star status is for the people at all levels and parts of the organization to talk together to get clear and aligned on just what they really want to do. How sincere and authentic is the desire to have safety excellence for the long-term? (This means Communication with a Capital C—requiring Co-creation, Clarity and Coherence.) In addition, together they must take the time to co-create a set of ground rules about how they agree to work together in order to achieve their safety goals and then hold each other accountable to live up to them. (That’s Partnership and Commitment!) The process to achieve this is available to you and your organizations now.

The keys for addressing both of these concerns in building sustainability into their programs and in achieving the OSHA Star status is for the people at all levels and parts of the organization to talk together to get clear and aligned on just what they really want to do. How sincere and authentic is the desire to have safety excellence for the long-term? (This means Communication with a Capital C—requiring Co-creation, Clarity and Coherence.) In addition, together they must take the time to co-create a set of ground rules about how they agree to work together in order to achieve their safety goals and then hold each other accountable to live up to them. (That’s Partnership and Commitment!) The process to achieve this is available to you and your organizations now.

There is no question that excellence in safety performance is good for both the people and the business. Creating and sustaining a workplace where everyone can go home injury-free, where everyone is treated respectfully, and everyone shares core safety values is what we should be doing.

In creating a workplace like this, the people are also generating benefit for the business. Eliminating OSHA Recordable Injuries and avoiding the average cost of $50,000 for each one provides real value for the business. Maintaining the production without the interruption of having had an injury and all the distraction that this causes is a also major contribution to the business. Building a reputation of being a safe, reliable supplier of quality produces another big value to the business.

Once everyone is clear and aligned that they really do want to achieve and sustain excellence, then talking together every day about doing this is critical. Toolbox meetings at shift start need to alert everyone on the challenges of working safely and a review of the day’s tasks, the looking out for the unexpected, taking two minutes before a job to be sure the right people and equipment are there, and emphasizing the importance of helping each other to stay alert and focused are also very important for these meetings.

As managers and supervisors walk around, they need to be talking respectfully with the people, listening and showing that they are really concerned for their safety. In doing this, we all learn together as better relationships develop and new ideas emerge. Talking with the people as true partners in the safety and business effort is key to moving to excellence. With everyone working together, on the same page, you are creating Partner-Centered Safety.

What are the overdue safety conversations you need to have?

And with whom?

What is it really all about?

This is all about having everyone go home in one piece and having a profitable business. Excellence in both the safety performance and business results are attainable.

This is all about having everyone go home in one piece and having a profitable business. Excellence in both the safety performance and business results are attainable.

When I was the plant manager at a big chemical plant, we got the total injury rates down to about 0.3, sustained this for 16 years, and had our earnings go up 300%. We have the roadmap that never fails—if you’re ready to travel that journey with us!

We can have it all if we want to do these things.

When the safety gets right, everything else gets right!

“

“ In my reading, studying and talking with many people, I have found that over half of the fatal accidents are often unanticipated and missed using our traditional approaches to accident prevention. The Heinrich Accident Triangle is very useful as we look at unsafe acts at the base of the triangle. Lots of slips, trips and falls are avoided as we do this.

In my reading, studying and talking with many people, I have found that over half of the fatal accidents are often unanticipated and missed using our traditional approaches to accident prevention. The Heinrich Accident Triangle is very useful as we look at unsafe acts at the base of the triangle. Lots of slips, trips and falls are avoided as we do this. Talking together is one of the most important things we can do to help to improve the safety in our workplaces. Letting people know that you care about them and respect them. But too many times I have seen supervisors and managers talking down to their employees ordering them to do this or that.

Talking together is one of the most important things we can do to help to improve the safety in our workplaces. Letting people know that you care about them and respect them. But too many times I have seen supervisors and managers talking down to their employees ordering them to do this or that. Each of us, as we travel to and from our work spaces want to be “safe and sound”—we want to return at the end of the day or at the end of our work-shift to our loved ones—safe and sound.

Each of us, as we travel to and from our work spaces want to be “safe and sound”—we want to return at the end of the day or at the end of our work-shift to our loved ones—safe and sound.  There are three main aspects to Partner-Centered Safety.

There are three main aspects to Partner-Centered Safety. Yes, the elephant that got in the way of having the conversations that matter? You did? Oh, you have one of those too?

Yes, the elephant that got in the way of having the conversations that matter? You did? Oh, you have one of those too? Another paper from an award-winning company showed their outstanding progress in lowering their total recordable injury rate from around 10 to 0.5 through a steady progress of improvements over 10 years. Their work was out of the Newtonian/Cartesian perspective, quite similar to what Mathis and Galloway teach.

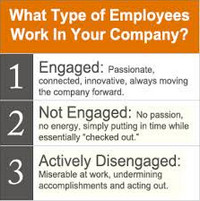

Another paper from an award-winning company showed their outstanding progress in lowering their total recordable injury rate from around 10 to 0.5 through a steady progress of improvements over 10 years. Their work was out of the Newtonian/Cartesian perspective, quite similar to what Mathis and Galloway teach. People are often reluctant to speak up in these negative environments. Ideas for improvement never surface. New employees are negatively influenced and led astray. Supervisors have a very rough time getting the people to do their work properly. Grievance rates are high and much time is wasted needlessly because these are not addressed at an early stage.

People are often reluctant to speak up in these negative environments. Ideas for improvement never surface. New employees are negatively influenced and led astray. Supervisors have a very rough time getting the people to do their work properly. Grievance rates are high and much time is wasted needlessly because these are not addressed at an early stage. For most managers putting production first can be quite subtle with messages like:

For most managers putting production first can be quite subtle with messages like: