The amount of change and the rate of change in the middle of DOGE is huge.

Different accounts and stories about what is happening swirl around like a storm. Organizations like NIOSH and OSHA are having to make adjustments for safety. Depending on the report, the stories of partial or even total elimination abound. Those of us outside the inner circles really do not know the details of what is happening, so we can get quite worked up about it all.

Some of the work being done in NIOSH may be vital in trying to improve workplace safety, but some of it may not be very important. From the outside, it is hard to tell. Hopefully any cuts in budget will focus on the less important work. NIOSH has been around for 50 years, and I’m told they’ve done much in the research end of safety and health.

As many of you know I have been asking why our fatality and injury rates are stuck at around 5,200 and 2.400,000 cases, respectively, for about the last 10 years. I do not know how the work of NIOSH directly impacts the workplace and in what ways their work has made the most difference. Based on the number of fatalities and injuries, you can make a case that NIOSH had very little impact so budget cutting may be the correct approach.

OSHA works closer to the actual workplace, thus having a more positive impact. But, again, the fatality and injury rates are not coming down so they may need to find out why that is.

I am more concerned about any OSHA budget cuts because OSHA is already spread very thin. OSHA has been around since 1970…can anyone say that our workplaces would be as safe as they are or that people would follow the safety rules that are in place without OSHA being the enforcer?

We Can Do a Lot Ourselves for Safety

Even though all the changes and cuts are happening, we can do a lot in our own workplaces at the local, company level to make a difference.

Workplace safety is a local issue, which we at the local level can impact regardless of all the other changes going on. What is the mindset we each can hold as to whether we will go home from the workplace today and every day with all our fingers, toes, legs, arms, eyes, and ears intact? What about how well we look out for our co-workers being able to also return home from work with body and mind wholeness?

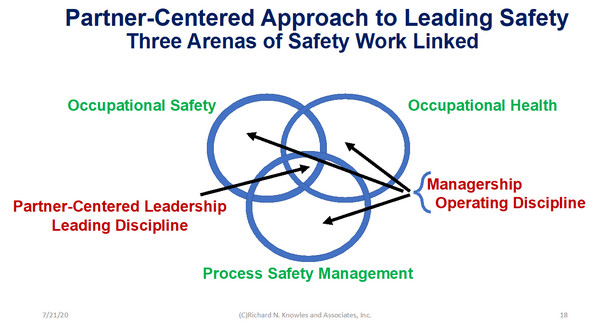

We can work directly with our people to help improve the total safety performance.

We can help our organizations get a whole lot better in all aspects of our work, not just in safety. We need to help all the people in the whole workplace to work more purposefully together. We need to treat each other with respect. Listen to each other. Help each other to share information more abundantly. Listen carefully to each other so we can learn together. We need to help people find meaning in their work and have more satisfaction with themselves.

When we work together doing these kinds of things, the whole workplace becomes much more open and healthier.

People do not have to fear that they will get punished in some way when they speak up and make suggestions. These kinds of behaviors positively impact all we do. In an environment like this, we can all learn and grow together.

I think that the only way we can create sustainable improvements in safety is to create a climate where everything in the organization is improving. And where people work to keep each other safe.

When I was the Plant Manager at a big plant that was having terrible performance problems, we on the Leadership Team decided to become the best producer and supplier of chemicals to our customers through improving all aspects of our work.

We focused on safety. environmental performance, people development, quality, customer service, costs, and our relationship with our community. Our total culture improved dramatically over the next 4 years, our injury rate dropped by 97%, emissions dropped by 95%, productivity rose by 45%, and earnings rose by 300%.

In the Midst of Great Change, We Can Do a Lot To Get Better!

We can take charge and sail our ships successfully in this great storm!

Call me at 716-622-6467 and let’s discuss how!

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread.

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread.