What every Manager needs to know that OSHA and ISO already do!

It started out in 1970 with OSHA’s regulations to enhance Safety in the Workplace – the first leg of the Safety Stool, a.k.a. as Occupational Safety, exampled by preventing slips, trips and falls, requiring hearing protection, hand and foot protection, and eye-ware.

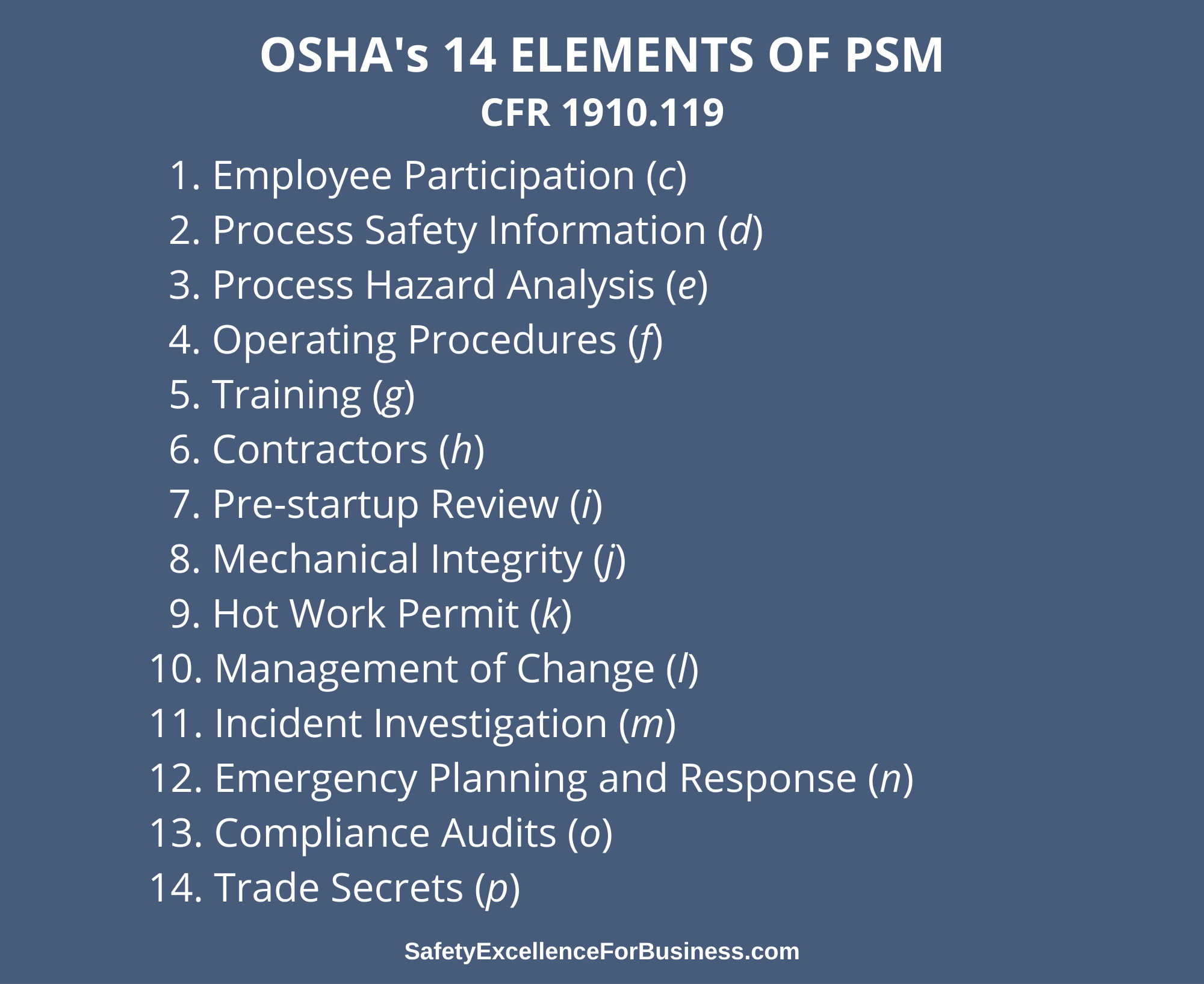

Then came the second leg of the Safety Stool, Occupational Health, exampled by preventing environmental/respiratory and ergonomic hazards. Then came Process Safety Management (PSM), exampled by what it takes to keep hazardous substances in the pipes, and which became an essential part of workplace safety with the comprehensive issuance of OSHA 1910 – the third leg.

All three legs are important and are critical for Safety professionals, HR professionals, Managers and Supervisors to embrace and for people to understand. Indeed, OSHA requires this attention to keep our people safe (life and limb) within the workplace.

Now, with this new decade of Workplace Violence rearing its ugly head, we know that we must add a fourth leg to the Safety Stool. Because attention to this 4th prong needs diligent awareness, it is now becoming paramount that every manager and supervisor be schooled in Situational Awareness:

- What is happening around you?

- What is happening between and among people in the workplace?

- Where are your vulnerabilities?

- Are you noticing the cultural dysfunction happening in your workplace?

- Are you able to engage appropriately to find out what’s happening?

- How do you address these dysfunctions?

The fourth leg of this stool is what is called Psychological or Social Safety. Another way to describe it is the psychological harm that comes with repeated bullying, harassment, incivilities, and dysfunctional behaviors, that leave workers dreading to go to work, or that increase the risk of home-growing an active threat/shooter, or having a suicide or murder in your workplace, let alone the bad press that comes with a highly publicized incident.

If no one steps in to stop bad behaviors when they are happening, they continue and escalate over time. Not paying attention to social risk manifests into psychological harm as the continuum of bad behaviors escalate in the workplace – and ultimately can impact people in harmful ways. Yes, OSHA is keen on this 4th leg of the safety stool, too, and wants to know what your business, company, organization, or team is doing about it. Prevention of Workplace Violence is the operative word.

What is Workplace Violence?

OSHA explains that workplace violence is violence or the threat of violence against workers. It can occur at or outside the workplace and can range from threats and verbal abuse to physical assaults and homicide, one of the leading causes of job-related deaths. However it manifests itself, workplace violence is a growing concern for employers and employees nationwide.

OSHA makes it very clear. Employers are responsible for ensuring that the workplace does NOT become a hostile workplace. (Bullying, harassment, and incivilities contribute to hostile environments). OSHA requires employers to provide a safe workplace for their employees…both physically safe and psychologically safe. This is covered by the General Duty Clause Section 5(a)(1).

Enter the new ISO Standard: ISO 45003 IS THE NEW INTERNATIONAL STANDARD (2021-06) – Occupational Health and Safety Management – Psychological health and safety at work – Guidelines for managing psychosocial risks. This new standard states that Management must be prepared to deal with violence that involves a person (employee, visitor, vendor), etc., losing control, without a weapon. This normally means dealing with psychological safety factors.

It is difficult to predict violent acts, so the Standard expects managers and associates to be vigilant. Report any concerns of erratic behaviors to supervision and HR as soon as possible.

Examples of violent behavior include but are not limited to:

- Intimidating or bullying others

- Abusive language

- Physical assault

- Threatening behavior

- Sexual or racial harassment

- Concealing or using a weapon

- Anger

- Tantrums

You get the picture. None of these types of behaviors belong in a workplace, thus the underscoring of new Respectful Workplace policies.

At Nagele, Knowles and Associates, we understand the construct of workplace violence and how to identify it. It starts with knowing your inside culture (culture assessment) to understand where bullying and dysfunctional behavior is happening and how to stop it in its tracks. What is your workplace doing to ensure a Respectful Workplace? It equally starts with a physical security vulnerability assessment to understand where you, your site, your people are most vulnerable to a perpetrator entering your workplace to do harm, and how to deter that from happening.

The 4th leg requires Situational Awareness – that is the tip of the spear when it comes to the prevention of workplace violence…from the inside or from the outside! This holds true in the workplace, and in living our daily lives. Wake up! Be Alert! Observing, expecting, embracing, and requiring a Respectful Workplace is powerful for reducing those harmful dysfunctional behaviors.

Employees must become stakeholders in their own safety and security and develop a survival mindset as well. Vigorous prevention programs, timely interventions, and appropriate responses by organizations and their employees will contribute significantly to a safe, secure, and respectful environment. That’s what we teach; that’s what we do.

Want to know more? Check out our book “Guide to Reducing the Risk of Workplace Violence…the Absolute Essentials” available on Amazon. It has been labeled the “gold standard” – a comprehensive guide to reducing your risk of workplace violence happening in your workplace…from the inside or the outside or give us a call at 716-622-6467.

I feel we are not moving fast enough to get to higher levels of performance. Way too many people are getting hurt and killed. Safety is a part of all we are doing and the whole system needs to be making improvements.

I feel we are not moving fast enough to get to higher levels of performance. Way too many people are getting hurt and killed. Safety is a part of all we are doing and the whole system needs to be making improvements. I was given the opportunity to talk about my work on Partner-Centered Leadership and shared information about the Process Enneagram, which is such a powerful tool to help people to come together to solve their complex problems. Partner-Centered Leadership is focused on sharing information, building trust and interdependence, helping everyone see the importance of their work for the success of the whole enterprise and moving into a better future. Everyone at the workshop was seeking ways to actually move into Safety II and make it happen so there was a lot of interest in this work.

I was given the opportunity to talk about my work on Partner-Centered Leadership and shared information about the Process Enneagram, which is such a powerful tool to help people to come together to solve their complex problems. Partner-Centered Leadership is focused on sharing information, building trust and interdependence, helping everyone see the importance of their work for the success of the whole enterprise and moving into a better future. Everyone at the workshop was seeking ways to actually move into Safety II and make it happen so there was a lot of interest in this work. A review of the Bureau of Labor Statics summary of fatal occupational injuries for 2011-2017 shows a 1% drop in fatalities from 2016 to 2017 to a total of 5,147 people having lost their lives at work. This is about 9% higher than the 4,693 people killed in 2011. The top three 2017 fatalities categories are roadway accidents totaling 1,299 (up 15% since 2011); slips, trips and falls totaling 887 (up 23% since 2011); and murders and suicides totaling 733 (up by only 2% since 2011).

A review of the Bureau of Labor Statics summary of fatal occupational injuries for 2011-2017 shows a 1% drop in fatalities from 2016 to 2017 to a total of 5,147 people having lost their lives at work. This is about 9% higher than the 4,693 people killed in 2011. The top three 2017 fatalities categories are roadway accidents totaling 1,299 (up 15% since 2011); slips, trips and falls totaling 887 (up 23% since 2011); and murders and suicides totaling 733 (up by only 2% since 2011). We need courageous leaders who focus on the people, change and the future. Leaders value sharing information, building trust and interdependence, and helping people to see how their job is important for the success of the whole venture.

We need courageous leaders who focus on the people, change and the future. Leaders value sharing information, building trust and interdependence, and helping people to see how their job is important for the success of the whole venture. Go into your organizations listening to and talking with the people. Share your vision. Build trust and interdependence. Create safe spaces for people to talk with each other, to share and create the future. Everything will change. That is what I experienced at the Belle Plant.

Go into your organizations listening to and talking with the people. Share your vision. Build trust and interdependence. Create safe spaces for people to talk with each other, to share and create the future. Everything will change. That is what I experienced at the Belle Plant. It is a new year. Businesses have compiled their 2018 safety statistics. They are looking at economics and at people. Who was hurt during this past year? What have we put in place so that those injuries won’t happen again? What are we talking about together for betterment? How did our systems contribute to our successes or to the injurie/s? What was the presence and the strength of Leadership support like around those people who were injured? Where are we most vulnerable safety-wise? How can we lead more effectively? How can we have an even safer workplace in this new year, 2019? How can we help employees to become more aware, more safety vigilant? And thus more able to return to their families at the end of the shift whole – with arms, legs, toes, fingers, eyes, ears – all intact. (Leaders, are you asking these questions?)

It is a new year. Businesses have compiled their 2018 safety statistics. They are looking at economics and at people. Who was hurt during this past year? What have we put in place so that those injuries won’t happen again? What are we talking about together for betterment? How did our systems contribute to our successes or to the injurie/s? What was the presence and the strength of Leadership support like around those people who were injured? Where are we most vulnerable safety-wise? How can we lead more effectively? How can we have an even safer workplace in this new year, 2019? How can we help employees to become more aware, more safety vigilant? And thus more able to return to their families at the end of the shift whole – with arms, legs, toes, fingers, eyes, ears – all intact. (Leaders, are you asking these questions?) There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry?

There is no doubt that work in the oil and gas industry is tough and dangerous, but that is no excuse for disregarding the health and safety of the workers. Almost all the deaths occurred when safety procedures were not followed. There is plenty of safety information available relating to tank cleaning. Have we not learned the lessons of improper confined space/vessel entry? Things do not have to be this way! Most of the people know that this is counter-productive but that is the way it is. However, when we engage the people from across the organization in the Complexity Leadership Process, guiding them in a purposeful conversation of discovery that changes everything, they find it does not have to be that way!

Things do not have to be this way! Most of the people know that this is counter-productive but that is the way it is. However, when we engage the people from across the organization in the Complexity Leadership Process, guiding them in a purposeful conversation of discovery that changes everything, they find it does not have to be that way!