I want to share some experiences I’ve learned about the importance of sharing information and building trust – especially as it applies to the various safety aspects of our workplaces.

We surely had our hands full in 2020 with all the COVID-19 issues. While the new vaccines will help, change will always be with us. Each of you can make a positive difference for the people in your organizations by sharing information about what is going on, building respect and trust and listening carefully, so you really understand the issues and concerns.

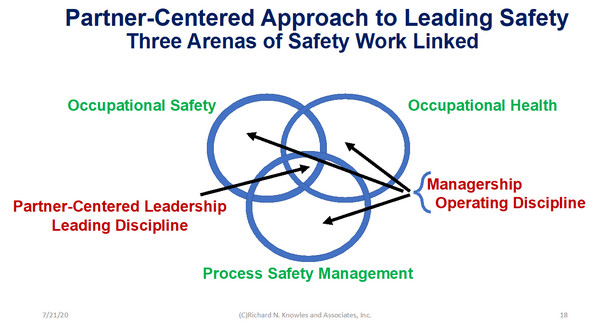

I have noticed that those working on occupational safety and occupational health do not interact much with the people working on process safety management (PSM), and vice-versa. For example, at the ASSP meetings, I rarely hear any one talking about PSM and at the AIChE Process Safety meetings, I don’t hear much about occupational safety and/or occupational health. It is as if these are different stove pipes. But each of these are areas where people are deeply involved in the total safety performance of the organization. I have found that when everyone is talking together about the total safety, synergy emerges and all areas benefit.

When I was the Plant Manager of a big chemical plant, the people working in these three areas were engaged in conversations and contributed to improvements across the board. This Venn Diagram illustrates how we brought them together while maintaining their unique contributions.

Each safety area was managed separately, using their own operating discipline. Where the three areas came together, we talked about what was happening and looked for input from each other. This significantly raised the total safety and environmental performance of the site. PSM also has a big impact on the environmental performance when spills, accidental chronic emissions, release incidents, improved yields and fires and explosions are eliminated; and a lot less is emitted to the environment.

The area of overlap of the three safety disciplines (at the center of the Venn diagram) is where we engaged in Partner-Centered Leadership:

- Sharing all information

- Building trust.

- Listening to each other’s problems and opportunities.

- Learning and finding better ways to do the work together.

For example, we talked about the three disciplines in our site Central Safety Meetings, keeping careful track of our safety workorder backlogs, meeting our safety equipment inspection schedules and talking about incidents and injuries that had happened, and what we could all learn from them. The engineers went into the various production areas and sat with the operators to learn what the operators were experiencing as they ran the processes, and the engineers taught the operators the engineering technology supporting their work, helping them to understand what was happening in the manufacturing operations. The supervisors, engineers, operators and maintenance people talked together as safety and work procedures were developed. The gap between work-as imagined and work-as-done virtually disappeared. As trust and the open dialogue improved, our safety and environmental performance really improved.

In just three years, the Total Recordable Injury Rate dropped by about 97% to a rate of about 0.3, and the people sustained this for 17 years. PSM improved with much lower levels of releases and upsets. The emissions to the environment (accidental and permitted) went down about 95% in four years. When the PSM was run as a separate stove pipe from the occupational safety and occupational health stove pipes, the Plant’s performance did not come anywhere close to these low levels. This is significant!

The improvements we made in how we worked together in safety spread into all the other parts of our work in running the big (1,300 people) chemical plant. The more we shared information, treated each other with respect and listened to each other, the more the total performance improved. For example, productivity rose by about 45% and earnings rose about 300%.

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread.

Learning to work more effectively, through our safety work, spread to the whole organization. Each of you reading this newsletter can make a big difference as you engage with the people in your organizations, sharing information, building respect and trust. The impact of your work will spread.

Want to know more? Contact me at 716-622-6467. Or, Order my book, “Partnering for Safety and Business Excellence” on Amazon.

Note: Venn is a diagram that shows all possible logical relations between a finite collection of different sets. Take a look at what sits right in the middle!

We each need to take the personal responsibility to try to avoid spreading the virus. With all the pressures, this is not easy. It is best if we each take personal responsibility to social distance and try to avoid spreading the virus. Government edicts really do not cover the details of what we each need to do very well. It is really up to us.

We each need to take the personal responsibility to try to avoid spreading the virus. With all the pressures, this is not easy. It is best if we each take personal responsibility to social distance and try to avoid spreading the virus. Government edicts really do not cover the details of what we each need to do very well. It is really up to us. In this story, a wicked witch puts the princess and the whole kingdom to sleep for 100 years. They all have to wait for the arrival of the prince to kiss the princess and awaken everyone. As children, we all knew this story, but in this new book, Stephen Capizzano shifts the story to thinking about what happens in our organizations.

In this story, a wicked witch puts the princess and the whole kingdom to sleep for 100 years. They all have to wait for the arrival of the prince to kiss the princess and awaken everyone. As children, we all knew this story, but in this new book, Stephen Capizzano shifts the story to thinking about what happens in our organizations. When we were able to shed our old habits at our Plant in West Virginia, injury rates dropped by 97%, emissions to air, ground and water as reported to the EPA dropped 95%, productivity rose by 45% and earnings rose by 300%. As I walked the plant for 5 hours each day we were reminding ourselves to shed the old habits and create a much brighter future.

When we were able to shed our old habits at our Plant in West Virginia, injury rates dropped by 97%, emissions to air, ground and water as reported to the EPA dropped 95%, productivity rose by 45% and earnings rose by 300%. As I walked the plant for 5 hours each day we were reminding ourselves to shed the old habits and create a much brighter future.

You can’t turn on the news or check your Internet homepage without sensing the depth of the issues that our country is experiencing. Whether it is returning to the workplace amidst COVID-19 rules, political protests, religious non-tolerance, or negative nightly news events – we’re experiencing a wide berth of dramatic events. And each of us has an opinion, a response, a way that we individually see these events and cope with this discord.

You can’t turn on the news or check your Internet homepage without sensing the depth of the issues that our country is experiencing. Whether it is returning to the workplace amidst COVID-19 rules, political protests, religious non-tolerance, or negative nightly news events – we’re experiencing a wide berth of dramatic events. And each of us has an opinion, a response, a way that we individually see these events and cope with this discord. It doesn’t have to be that way! Take a timeout!

It doesn’t have to be that way! Take a timeout! In times like this, when the business and production activities are ramping up, there is a real danger that safety problems will show up. Any time the level of activity changes, up or down, is a time of danger.

In times like this, when the business and production activities are ramping up, there is a real danger that safety problems will show up. Any time the level of activity changes, up or down, is a time of danger. It will not be easy as people are returning to the workplace. Leaders and managers must get out of their offices and purposefully engage with the people. They need to talk about the COVID-19 problem, share what is happening, and talk about the problems with which they are dealing. They need to do this with openness, honesty, respect, and caring. This is not just a one-off contact; leaders and managers need to engage in these conversations every day!

It will not be easy as people are returning to the workplace. Leaders and managers must get out of their offices and purposefully engage with the people. They need to talk about the COVID-19 problem, share what is happening, and talk about the problems with which they are dealing. They need to do this with openness, honesty, respect, and caring. This is not just a one-off contact; leaders and managers need to engage in these conversations every day! I have abstracted it here for those reading this newsletter since you may have missed it.

I have abstracted it here for those reading this newsletter since you may have missed it. In all cases, the healthcare provider and local health department should be consulted.

In all cases, the healthcare provider and local health department should be consulted. This pandemic has created a lot of change and instability in our society. The FDA and the CDC have changed or suspended many rules and regulations in order to attack the pandemic and save lives. It is a period of high energy and creativity as people everywhere are coming up with ways to help people. Industries have shifted to making PPE-like face masks. The foodservice industry has shifted to take out and delivery. This creativity and positive energy is gratifying.

This pandemic has created a lot of change and instability in our society. The FDA and the CDC have changed or suspended many rules and regulations in order to attack the pandemic and save lives. It is a period of high energy and creativity as people everywhere are coming up with ways to help people. Industries have shifted to making PPE-like face masks. The foodservice industry has shifted to take out and delivery. This creativity and positive energy is gratifying.