With all the information flowing around about the Coronavirus 2019 (COVID-19), it seems very easy to get quite alarmed and concerned.

Like all flus, we need to take it seriously and take appropriate steps to protect ourselves and our families. I have read a lot about what employers should do to protect their employees, which makes sense, but it sounds as if they are running a kindergarten class. OSHA has declared the flu as a recognized workplace hazard, so employers do have a responsibility to do what they can to protect the people, but there is a lot we can do for ourselves.

Like all flus, we need to take it seriously and take appropriate steps to protect ourselves and our families. I have read a lot about what employers should do to protect their employees, which makes sense, but it sounds as if they are running a kindergarten class. OSHA has declared the flu as a recognized workplace hazard, so employers do have a responsibility to do what they can to protect the people, but there is a lot we can do for ourselves.

It seems to me that there are two basic things we each can do. First is to take responsibility for ourselves and the second is to avoid situations where we may get the flu.

We can all do things like…

- Staying away from work and other people if we are coming down with flu symptoms. If we get the symptoms, then don’t go around exposing others.

- Working from home, if we can, to avoid others.

- Washing our hands often, soaping them for 20 seconds or so.

- Keeping our hands away from our faces so we do not put the flu virus right into our nose or mouth.

- Using disinfectant wipes to clean our cell phones, shopping cart handles, etc.

- Cleaning our work stations and computer keyboards.

- Using proper coughing etiquette.

Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place.

Artificial intelligence and robots, block chains and bitcoins, the opioid epidemic, political strife, and workplace violence, international worries and potential conflicts are some of the challenges facing all of us. There is a critical need for people, in all walks of life, to come together to openly and honestly talk about our challenges, share our thinking and learn together. We do not have to be blindly swept along. We can make decisions and do the things that we need to do to help to make the world a better place. When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed.

When I talk about safety. my thinking goes well beyond the traditional safety numbers, training and procedures. It includes ideas about respect and how everyone has agreed to work together. It includes ideas about personal responsibility, integrity and dedication to helping everyone improve. It includes openness, honesty and sharing information abundantly. It includes ideas about the deeper, often hidden patterns of behavior which have a profound impact on the work environment and drive much of the behavior. It includes the fact that the managers and leaders have the largest impact on their organization’s performance. It includes the understanding that managers focus on reliability, stability, predictability and control as they try to maintain the status quo and that leaders focus on the people, change and the future sharing information abundantly, treating people with respect and helping people find meaning in their work. Both good leaders and managers are needed. This begins with the leaders deciding to create a culture where it is okay and encouraged that people genuinely talk together, listen, help each other, look out for each other and learn together. This is a culture that helps people to be the best they can be and for the organization to get a lot more profitable. It all begins with all of us treating each other with respect.

This begins with the leaders deciding to create a culture where it is okay and encouraged that people genuinely talk together, listen, help each other, look out for each other and learn together. This is a culture that helps people to be the best they can be and for the organization to get a lot more profitable. It all begins with all of us treating each other with respect. This is the sort of culture that Eric Hollnagel is talking about in his Safety II work, which is intended to move the organization beyond the traditional top-down safety management. (I’ve written about Safety II in previous articles – it is all good!)

This is the sort of culture that Eric Hollnagel is talking about in his Safety II work, which is intended to move the organization beyond the traditional top-down safety management. (I’ve written about Safety II in previous articles – it is all good!)

There have been five fatalities since the project began. All five of the fatalities have been “struck-by” incidents. The most recent occurred about October 1st, when a beam slipped off a piece of equipment and struck a worker on the head. One person was hit by a dump truck. Another died when he was hit by a piece of steel equipment. The fourth person died when a rebar cage fell on him, and the fifth person was killed when he was hit in the head by a pipe.

There have been five fatalities since the project began. All five of the fatalities have been “struck-by” incidents. The most recent occurred about October 1st, when a beam slipped off a piece of equipment and struck a worker on the head. One person was hit by a dump truck. Another died when he was hit by a piece of steel equipment. The fourth person died when a rebar cage fell on him, and the fifth person was killed when he was hit in the head by a pipe. For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM.

For example, the workers on the Deepwater Horizon drilling platform received good recognition for outstanding occupational safety performance (the slips, trips and falls sorts of incidents) just a day or two before the explosion on April 20, 2010, that killed 11 people and injured 17 others. The pressures from top management to get into production led to failures of their process safety management (PSM) systems and processes. Communications were limited because management did not want to hear of more problems; they were driving the production schedule. The fine occupational safety performance masked the PSM deficiencies which are more subtle and invisible to upper managers, unless they are keenly aware of the needs for excellent PSM. Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production.

Now we have another example with the mess at Boeing and the 737 Max crashes. Top management was feeling the pressures for market share from Airbus and putting terrific pressures on cost reduction and faster production. There seems to be an interesting disconnect here. OSHA does focus on falls, but what about roadway deaths and homicides? These are serious workplace problems as well. What about the whole problem of workplace violence that begins with the lack of respect (bullying, harassment), and that can lead to serious business problems like poor productivity, high absenteeism, fighting, injuries, murder, and suicide?

There seems to be an interesting disconnect here. OSHA does focus on falls, but what about roadway deaths and homicides? These are serious workplace problems as well. What about the whole problem of workplace violence that begins with the lack of respect (bullying, harassment), and that can lead to serious business problems like poor productivity, high absenteeism, fighting, injuries, murder, and suicide? This is quite attainable with authentic, courageous leaders who take a stand that this is the sort of place they want to lead. The knowledge and technology are available and broadly known by lots of people so I want to share my own experiences.

This is quite attainable with authentic, courageous leaders who take a stand that this is the sort of place they want to lead. The knowledge and technology are available and broadly known by lots of people so I want to share my own experiences. This all began with my determination to work on improving respect, civility and safety. As I built credibility and trust with everyone, people began to make improvements in many other areas. Everything got better.

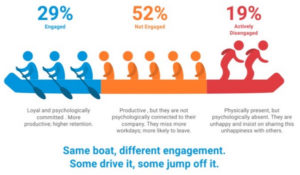

This all began with my determination to work on improving respect, civility and safety. As I built credibility and trust with everyone, people began to make improvements in many other areas. Everything got better. In 2017, Gallup, Inc. published their “State of the Global Workplace,” looking at the levels of productivity around the world. They were concerned about the decline in productivity and wanted to develop a better picture of the situation. High productivity is a key to having a good quality of life, and this relates to how involved people are in their work. They found that worldwide, only about 15% of the people are highly involved. This varies from country to country with the highest levels of involvement in the USA and Canada at 31%. Those businesses in the top quartile of employee involvement in their global study are 21% more profitable and 17% more productive. They also have 70% fewer safety incidents, 40% fewer quality incidents, 41% lower absenteeism, and 59% lower turnover. The positive impact of employees being highly involved is huge.

In 2017, Gallup, Inc. published their “State of the Global Workplace,” looking at the levels of productivity around the world. They were concerned about the decline in productivity and wanted to develop a better picture of the situation. High productivity is a key to having a good quality of life, and this relates to how involved people are in their work. They found that worldwide, only about 15% of the people are highly involved. This varies from country to country with the highest levels of involvement in the USA and Canada at 31%. Those businesses in the top quartile of employee involvement in their global study are 21% more profitable and 17% more productive. They also have 70% fewer safety incidents, 40% fewer quality incidents, 41% lower absenteeism, and 59% lower turnover. The positive impact of employees being highly involved is huge. Most people in management positions focus on systems and processes like running a payroll or production line. They want reliability, predictability, control, and stability, which are important for much of the business. But when they apply this approach to people, things go downhill. This approach results in 71% of the people globally being unengaged and 19% being actively disengaged. Morale, safety and engagement are a mess. Managers engage in managership, and this will not solve the problem of building higher levels of engagement.

Most people in management positions focus on systems and processes like running a payroll or production line. They want reliability, predictability, control, and stability, which are important for much of the business. But when they apply this approach to people, things go downhill. This approach results in 71% of the people globally being unengaged and 19% being actively disengaged. Morale, safety and engagement are a mess. Managers engage in managership, and this will not solve the problem of building higher levels of engagement.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing.

The way in which we think about and work with all the people is a key shift that is needed.Leading thinkers like Eric Hollnagel, Tom McDaniel, Beth Lay, Carl Stent, and Ron Gantt are searching for better, more effective ways of engaging with everyone to build on the good things people are doing. I feel we are not moving fast enough to get to higher levels of performance. Way too many people are getting hurt and killed. Safety is a part of all we are doing and the whole system needs to be making improvements.

I feel we are not moving fast enough to get to higher levels of performance. Way too many people are getting hurt and killed. Safety is a part of all we are doing and the whole system needs to be making improvements. I was given the opportunity to talk about my work on Partner-Centered Leadership and shared information about the Process Enneagram, which is such a powerful tool to help people to come together to solve their complex problems. Partner-Centered Leadership is focused on sharing information, building trust and interdependence, helping everyone see the importance of their work for the success of the whole enterprise and moving into a better future. Everyone at the workshop was seeking ways to actually move into Safety II and make it happen so there was a lot of interest in this work.

I was given the opportunity to talk about my work on Partner-Centered Leadership and shared information about the Process Enneagram, which is such a powerful tool to help people to come together to solve their complex problems. Partner-Centered Leadership is focused on sharing information, building trust and interdependence, helping everyone see the importance of their work for the success of the whole enterprise and moving into a better future. Everyone at the workshop was seeking ways to actually move into Safety II and make it happen so there was a lot of interest in this work.